Meat processing plants

Modular meat processing plants that adapt to your production needs

Finmodules meat processing plants provide a versatile solution for the equally versatile needs of the food industry. Thanks to their modular structure, our meat processing systems are ideal for a variety of operations from meat cutting and processing to storage.

👇 Learn more about our modular meat processing plants in the drop-down selector below and download a product card.

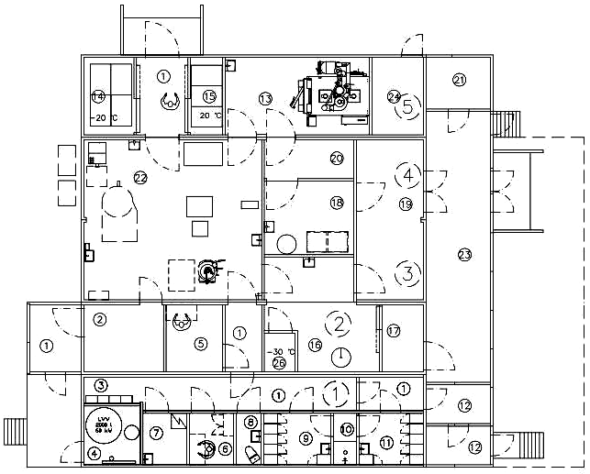

TECHNICAL INFORMATION

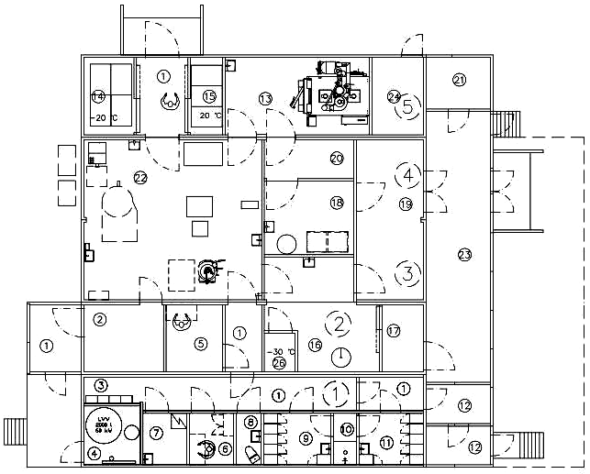

| Capacity | Sausages and meat products 1.000 kg / shift |

| Capacity, ready-meal products (dumplings) | 200 kg / shift |

| Number of modules | 5 pcs |

| Size approx. | 210 m2 |

Technical information

| Products | Cooked and smoked sausages

Frankfurter Dumplings |

| Capacity | Sausages and meat products 1.000 kg / shift

Dumplings 200 kg / shift |

External connections

| Electricity | 400 V, 50 Hz, 400 A |

| Water | 70 – 100 l/min, 4 bar, 2” |

| Waste water | ø 160 mm |

| Number of modules | 5 kpl |

| Size approx. | 210 m2 |

Meat processing units

- Social premise

- Production premise

- Cutting- and packing premises (2)

- Receiving premise for raw material

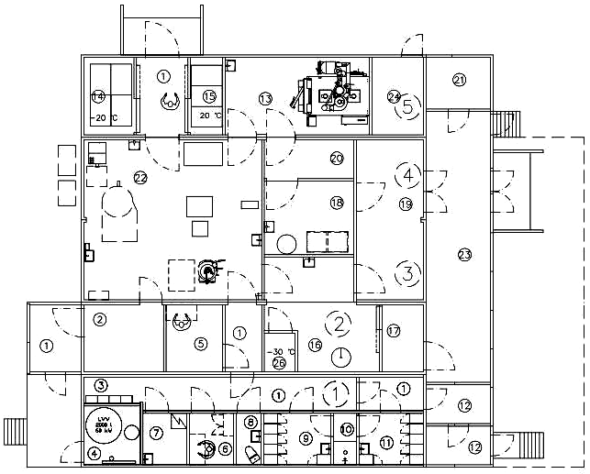

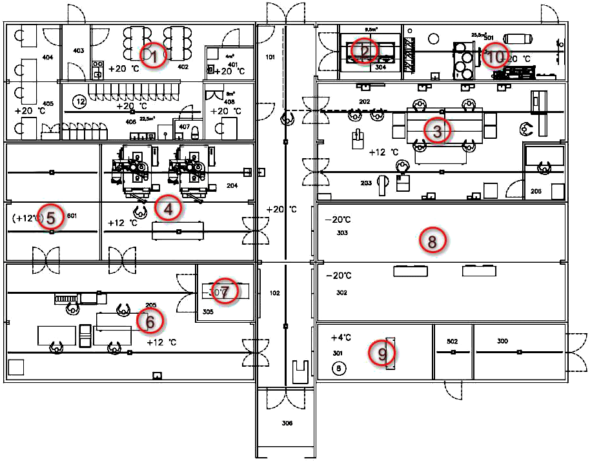

TECHNICAL INFORMATION

| Capacity | Sausages, cold- and warm smoked products, full meat products 2.000 kgs / shift |

| Number of modules | 6 pcs |

| Size approx. | 252 m2 |

Technical information

| Capacity | 2.000 kgs / shift |

| Products | sausages, cold- and warm smoked products, full meat products |

External connections

| Electricity | 400 V, 50 Hz, 200 A |

| Water | 50 l / min, 4 bar, 2” |

| Waste water | ø 110 mm |

| Number of modules | 6 kpl |

| Size approx. | 252 m2 |

Meat processing plant units

- Technical- and social premises

- Production premise

- Production- and packing premise

- Freezing storage

- Freezing tunnel and -storage

- Receiving premise for carcasses

- Technical premise

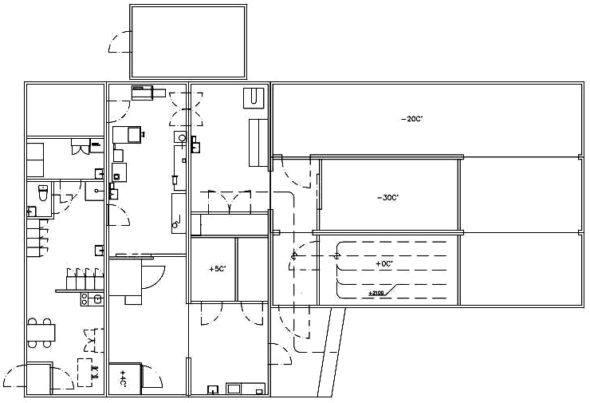

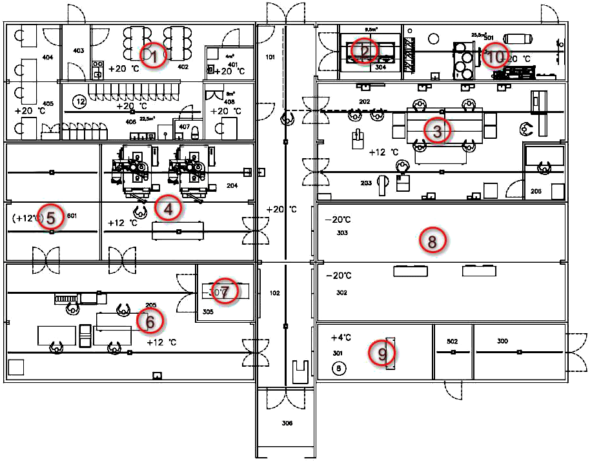

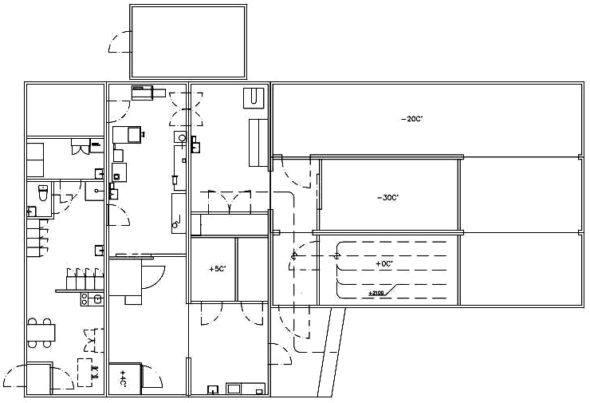

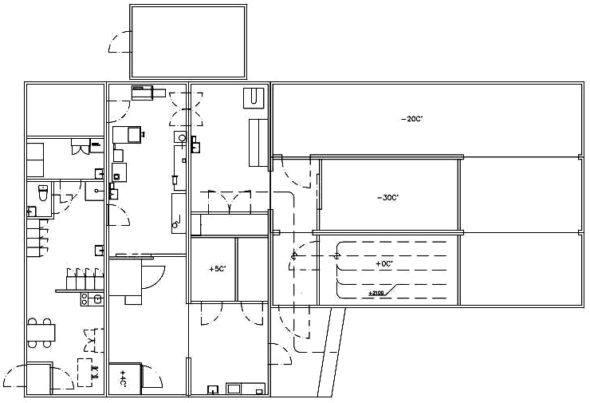

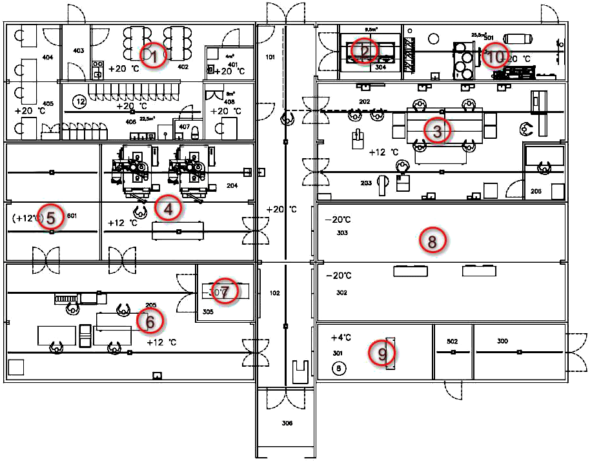

TECHNICAL INFORMATION

| Capacity | Sausages, cold- and warm smoked products, full meat products 4.000 kgs / shift |

| Number of modules | 14 pcs |

| Size approx. | 588 m2 |

Technical information

| Capacity | 4.000 kgs / shift |

| Products | sausages, cold- and warm smoked products, full meat products |

External connections

| Electricity | 400 V, 50 Hz, 2 x 200 A |

| Water | 50 l / min, 4 bar, 2” |

| Waste water | ø 110 mm |

| Number of modules | 14 kpl |

| Size approx. | 588 m2 |

Meat processing plant units

- Technical- and social premises

- Production premise

- Production- and packing premise

- Freezing storage

- Freezing storage

- Warehouse for finished products

- Technical premises

Custom solutions tailored for your production

Meets the strict standards of the food industry

Cost-effective meat processing systems

Why choose Finmodules meat processing facilities

Flexible solutions that adapt to changes in capacity

Thanks to their modular structure, Finmodules meat processing plants are easy to customize to provide the best solutions for different needs. For a small operation, a daily capacity of 500 kg may be sufficient, but when operations grow, we can scale up the capacity to up to 20 000 kg/day.

Combine various processing facilities – we provide the complete delivery

Before meat can be processed, the animal needs to be slaughtered. Kometos delivers every part of the production chain as a complete solution. We can integrate other facilities into the meat production plant, such as a mobile slaughterhouse or a thawing system.

Durable processing plants even for the most demanding conditions

All Finmodules production facilities are built with durable and long-lasting materials. They withstand big temperature fluctuations which makes them ideal for even the most demanding conditions. We have delivered meat processing facilities across the globe, from Siberia to South Africa.

What kind of products are Finmodules meat processing plants suitable for?

The possibilities are nearly endless. The modular structure allows the production plants to be equipped with a variety of machinery and facilities.

Examples of operations and processed products include:

- meat cutting

- boiled or cooked meat products

- marinated products

- hot and cold smoked meat

- frozen products

- canned products

- minced meats

- sausages and cold cuts.

Case: Meat processing startup cut down the production time of air-dried meats by a third

A Finnish meat processing startup was sniffing out local food trends. It seemed that Finnish tastes were starting to take on influences from Central Europe. Seeing a new market opportunity emerge, the company decided to start the production of air-dried meat products.

Typically, producing air-dried meat is a long process. The traditional production method takes 3-30 months, but with new technology, provided by Kometos, the time was cut down significantly. The new production method was sped up by a third.

The traditional production method is also investment-heavy. Meat has to be stored for a long time, which means large investments in storage space. The production also requires a lot of energy. Thanks to faster production, energy is saved and the need for storage is smaller. This also increases the production capacity.

- The plant utilizes reverse defrosting technology.

- Kometos provided the complete solution: HEPAC, electricity, as well as communications and paperwork with the public officials.

We chose Kometos because it was so easy. This is a package deal, and the cooperation has been excellent.

– Jari Paakkunainen, CEO, Bonus Carnis

We always tailor the solution to our client’s needs. Our modular facilities are easy to combine, customize and, if needed, scale and modify later. For instance, we can integrate a slaughterhouse, production facilities, freezing, and thawing in one complete solution.

All our deliveries are so-called complete deliveries. It means that we build, equip, and test the production facilities at our factory first. We handle the installation and train your staff to operate and maintain the facilities.

In the Finmodules product line, we have custom solutions for processing fish and seafood.

Our modular production facilities are very versatile: they’re also suitable for processing dairy, berries, and juices. Contact us for a custom solution.