Freezing systems

Finncold freezing systems for efficient food industry freezing

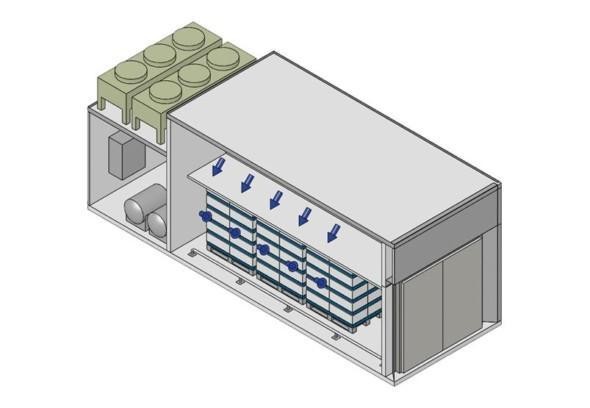

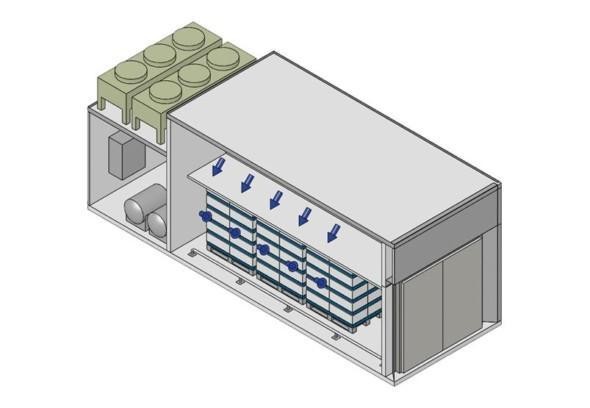

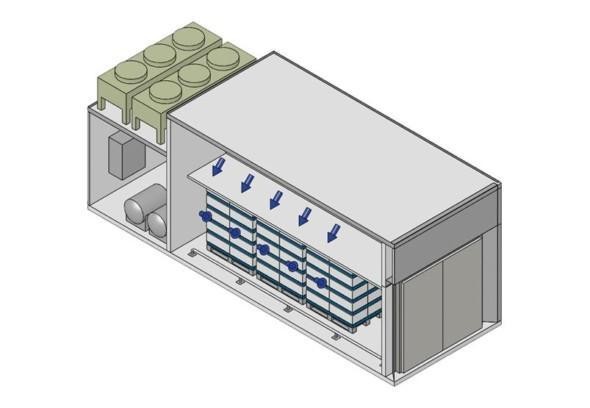

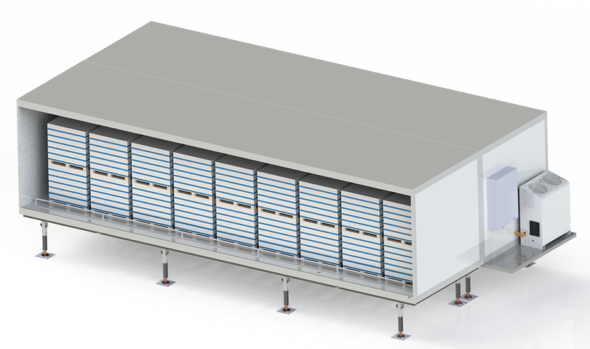

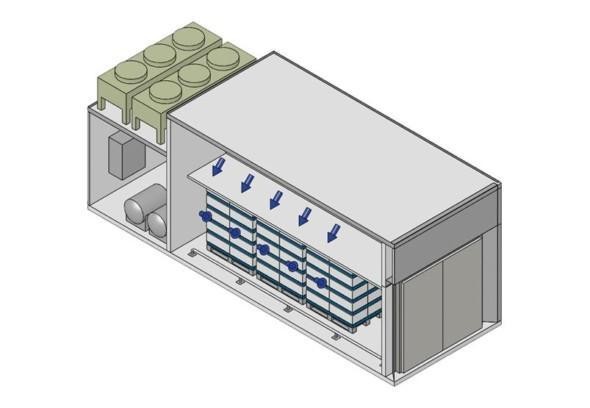

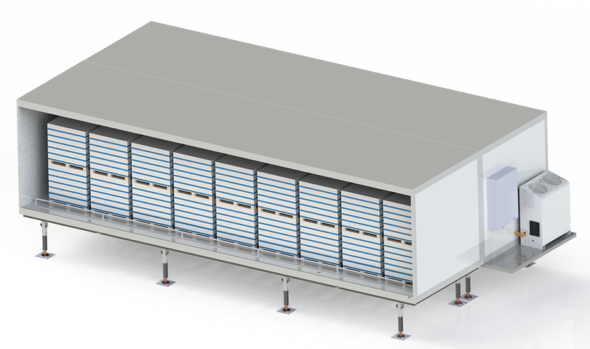

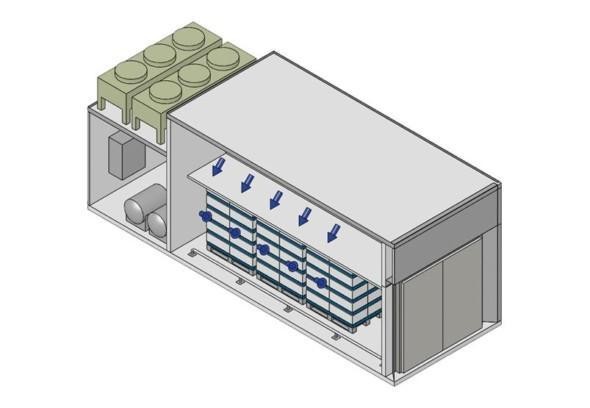

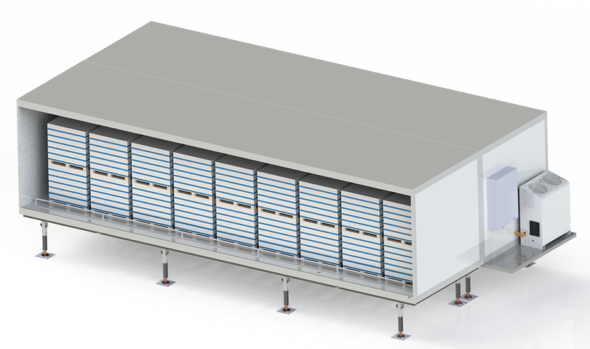

The modular Finncold freezing systems guarantee fast and controlled freezing that keeps your food products fresh and high-quality. Our freezing rooms are designed to meet the strict hygiene and quality standards of the food industry.

👇Learn more about our models in the drop-down selector below and download a product card for specific product below the technical information.

In need of a customized solution? Contact us.

TECHNICAL INFORMATION

| Size | 5600 x 2900 x 3500 |

| Capacity | 6 Euro pallets or 2.500 kg / Process |

Technical information

| Size | 5600 x 2900 x 3500 |

| Capacity | 6 Euro pallets or 2.500 kg / Process |

| Area of activity | +5 °C …-20 °C, freezing on pallets / gratings, block size 600 x 400 x 150 mm |

| Freezing time | varies by product and by packaging.

Indicative times are: +5 °C…- 20 °C, 18 – 22 h |

| Frame | Self-supported, specially designed welded metal frame with 6 pc supporting legs. |

| Weight | Total weight appr. 4500 kg |

| Connection data | Electrical connection: 3 x 400 V / 100A.

Drain connection, for condensation water. |

| Cooling | Hermetic refrigeration compressor together with condenser and evaporator, refrigerant R449, cooling capacity of 23 kW (-35 °C /+32 °C).

A cooling evaporator coil electric defrost. |

| Air circulation | Air circulation with propeller fans. |

| Intermediate level / air control | Solid intermediate level |

| Control | Thermostat controlled freezing process. Operating switches on the door frame. |

TECHNICAL INFORMATION

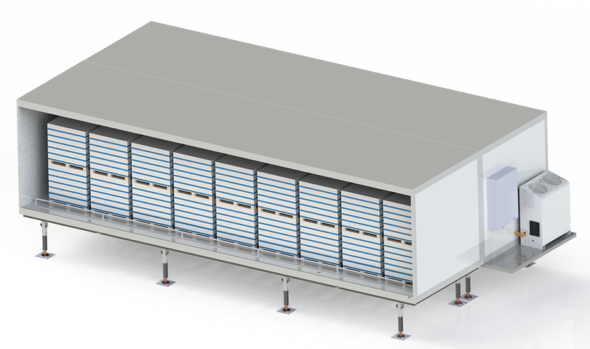

| Size | 9725 x 3200 x 3500 |

| Capacity | 12 Euro pallets or 5.000 kg / Process |

Technical information

| Size | 9725 x 3200 x 3500 |

| Capacity | 12 Euro pallets or 5.000 kg / Process |

| Area of activity | +5 °C …-20 °C, freezing on pallets / gratings, block size 600 x 400 x 150 mm |

| Freezing time | varies by product and by packaging.

Indicative times are +5 °C…- 20 °C, 18 – 22 h |

| Frame | Self-supported, specially designed welded metal frame with 8 pc supporting legs. |

| Weight | Total weight appr. 5 500 kg. |

| Connection data | Electrical connection: 3 x 400 V / 160 A.

Drain connection, for condensation water. |

| Cooling | Hermetic refrigeration compressor together with condenser and evaporator, refrigerant R449, cooling capacity of 2 x 23 kW (-35 °C /+32 °C).

A cooling evaporator coil electric defrost. |

| Air circulation | Air circulation with propeller fans. |

| Intermediate level / air control |

Solid intermediate level. |

| Control | Thermostat-controlled freezing process. Operating switches on the door frame. |

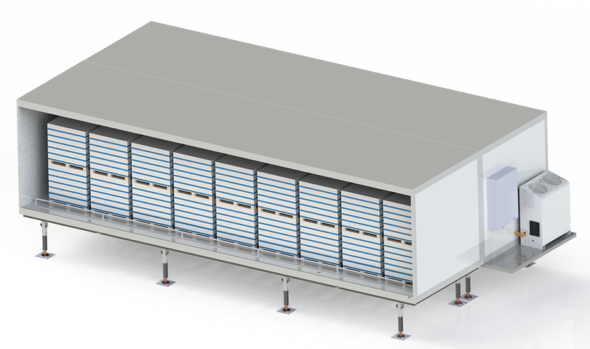

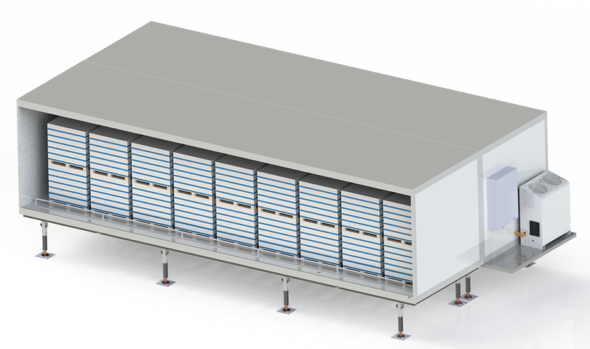

TECHNICAL INFORMATION

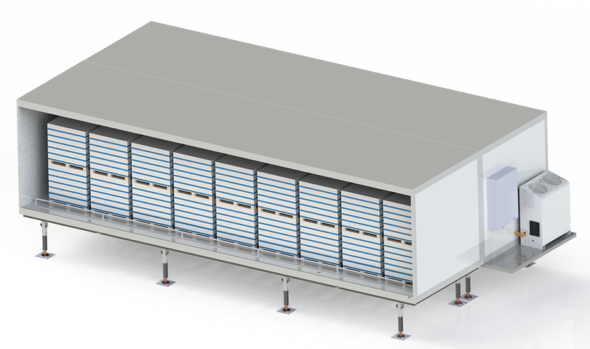

| Size | 13400 x 3500 x 3500 |

| Capacity | 20 Euro pallets or 10.000 kg / Process |

Technical information

| Size | 13400 x 3500 x 3500 |

| Capacity | 20 Euro pallets or 10.000 kg / Process |

| Area of activity | +5 °C …-20 °C, freezing on pallets / gratings, block size 600 x 400 x 150 mm |

| Freezing time | varies by product and by packaging.

Indicative times are +5 °C…- 20 °C, 18 – 22 h |

| Frame | Self-supported, specially designed welded metal frame with 8 pc supporting legs. |

| Weight | Total weight appr. 7 000 kg. |

| Connection data | Electrical connection: 3 x 400 V / 260 A.

Drain connection, for condensation water. |

| Cooling | Hermetic refrigeration compressor together with condenser and evaporator, refrigerant R449, cooling capacity of 4 x 23 kW (-35 °C /+32 °C).

A cooling evaporator coil electric defrost. |

| Air circulation | Air circulation with propeller fans. |

| Intermediate level / air control | Solid intermediate level. |

| Control | Thermostat-controlled freezing process. Operating switches on the door frame. |

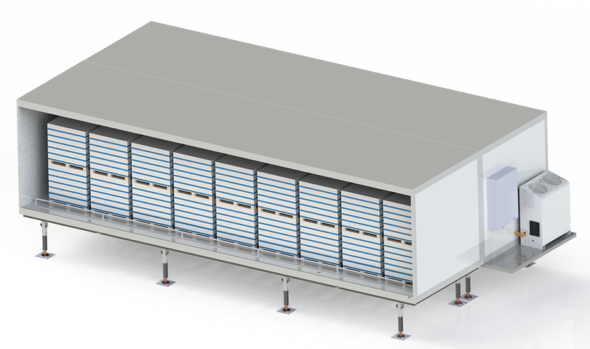

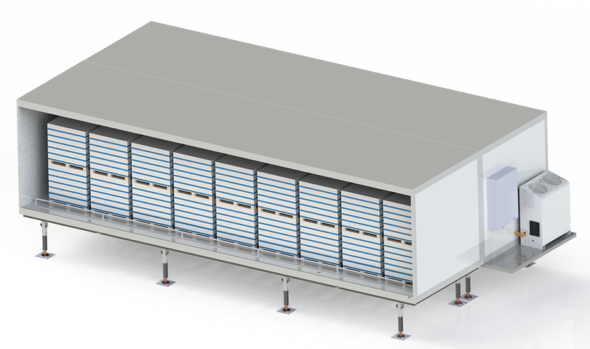

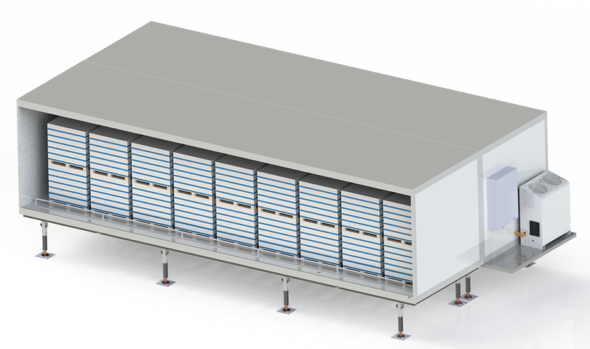

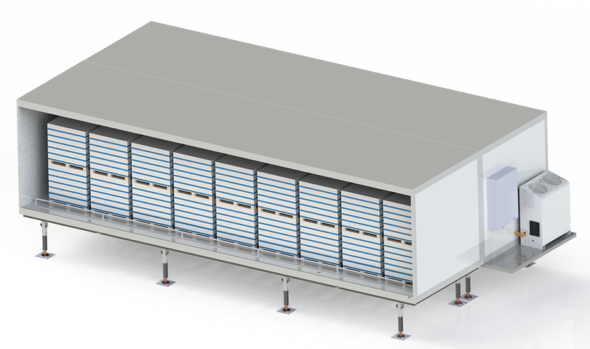

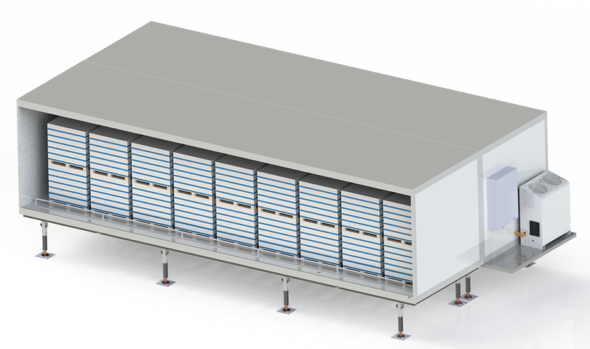

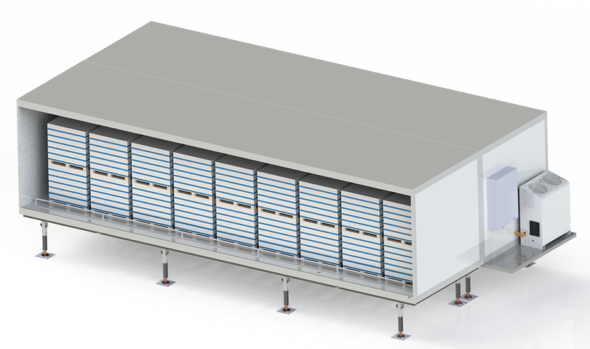

TECHNICAL INFORMATION

| Size | 13400 x 3200 x 3500 |

| Capacity | 30 Euro pallets or 15.000 kg |

Technical information

| Size | 13400 x 3200 x 3500 |

| Capacity | 30 Euro pallets or 15.000 kg |

| Area of activity | -20 °C, FiLo |

| Frame | Self-supported, specially designed welded metal frame with 10 pc supporting legs. |

| Weight | Total weight appr. 14 000 kg. |

| Connection data | Electrical connection: 3 x 400 V / 36 A.

Drain connection, for condensation water. |

| Cooling | Hermetic refrigeration compressor together with condenser and evaporator, refrigerant R449, cooling capacity of 13 kW (-20°C /+32 °C).

A cooling evaporator coil electric defrost. |

| Air circulation | Air circulation with propeller fans. |

| Control | Thermostat-controlled freezing process. Operating switches on the door frame. |

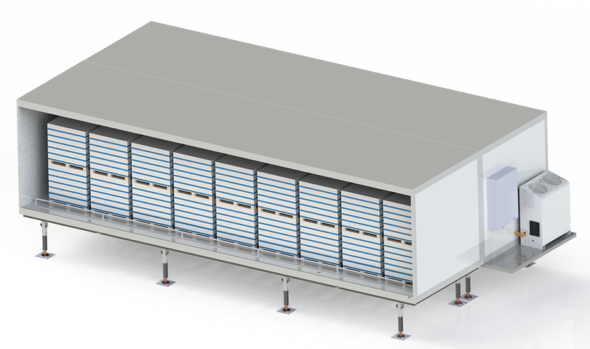

TECHNICAL INFORMATION

| Size | 13400 x 6400 x 3500 |

| Capacity | 2 x 36 Euro pallets or 2 x 20.000 kg |

Technical information

| Size | 13400 x 6400 x 3500 |

| Capacity | 2 x 36 Euro pallets or 2 x 20.000 kg |

| Area of activity | -20 °C, FiLo |

| Frame | Self-supported, specially designed welded metal frame with 16 pc supporting legs. |

| Weight | Total weight appr. 14 000 kg. |

| Connection data | Electrical connection: 3 x 400 V / 36 A.

Drain connection, for condensation water. |

| Cooling | Hermetic refrigeration compressor together with condenser and evaporator, refrigerant R449, cooling capacity of 13 kW (-25 °C /+32 °C).

A cooling evaporator coil electric defrost. |

| Air circulation | with propeller fans. |

| Control | Thermostat-controlled freezing process. Operating switches on the door frame. |

TECHNICAL INFORMATION

| Size | 13400 x 6400 x 3500 |

| Capacity | 2 x 36 Euro pallets or 2 x 20.000 kg |

Technical information

| Size | 13400 x 6400 x 3500 |

| Capacity | 2 x 36 Euro pallets or 2 x 20.000 kg |

| Area of activity | +4 °C, FiLo |

| Frame | Self-supported, specially designed welded metal frame with 20 pc supporting legs. |

| Weight | Total weight appr. 14 000 kg. |

| Connection data | Electrical connection: 3 x 400 V / 36 A.

Drain connection, for condensation water. |

| Cooling | Hermetic refrigeration compressor together with condenser and evaporator, refrigerant R449, cooling capacity of 18 kW (+4°C/+37 °C).

A cooling evaporator coil electric defrost. |

| Air circulation | with propeller fans. |

| Control | Thermostat-controlled. Operating switches on the door frame. |

Modular freezing rooms are ideal for customization

Hygiene standards approved for the food industry

30+ years of experience in freezing and cold storage

Why choose Finncold freezing systems

Suitable for all food production freezing

Our freezing rooms and freezer storage units are suitable for freezing all food products. Our freezing tunnels are used, for example, for freezing and cold storing meat, poultry, and fish, as well as ready-to-eat meals.

Fast and efficient freezing guarantees high-quality products

The faster you freeze the food, the better its structure and quality remain. Our efficient cooling and air circulation system guarantees a fast and controlled freezing process.

Meets the food industry freezing standards

In the food industry, hygiene comes first. Our freezing tunnels and freezer storage are built with special elements designed and approved for the food industry.

Cold storage in up to -30 °C

On top of cooling and freezing the food, our freezing rooms double as freezer storage containers. You can store food products in up to -30 Celsius degrees.

Flexible solution for different needs

When your business and production capacity grows, our modular freezing units grow along. The freezing systems can be modified and moved according to your needs. The freezing system can also be placed outside the plant premises.

Turnkey delivery

From testing the units to final installation, we deliver the freezing system to you as a turnkey solution. As one of our customers said: “Just plug it in and turn on the power – that’s all we had to do. Kometos took care of the rest, from start to finish.”

How to minimize drip losses?

When defrosting food products, some liquid is always released. But the Finncold thawing systems keep the defrost losses as low as 1% of the weight of the product.

Finncold units are suitable for a variety of products

Meat and poultry

-

Raw meat, such as beef, pork, lamb, or reindeer

-

Poultry, such as chicken, turkey, or duck

-

Cooked meat products, such as sausages, nuggets, or meatballs

-

Ready meals

Fish and seafood

- Fish

- Shrimp and prawn

- Shellfish, crab, and crayfish

- Squid and octopus

- Scallop, oyster, and mussel

- Seafood products, such as smoked fish, fish fingers, or fish cutlets

Fruits, vegetables, and potatoes

- Raw or precooked vegetables

- Potato wedges, french fries, and other potato products

- Fruits

- Berries

Bakery products

- Bread

- Confectionary products

- Buns, rolls, and biscuits

- Cakes, pastries, and other baked goods

Didn’t find your product on the list? Ask for more information.

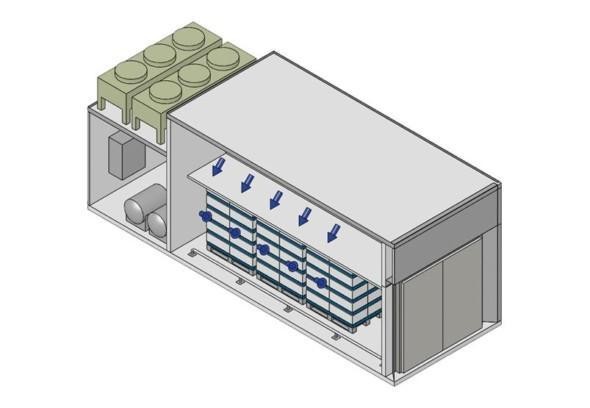

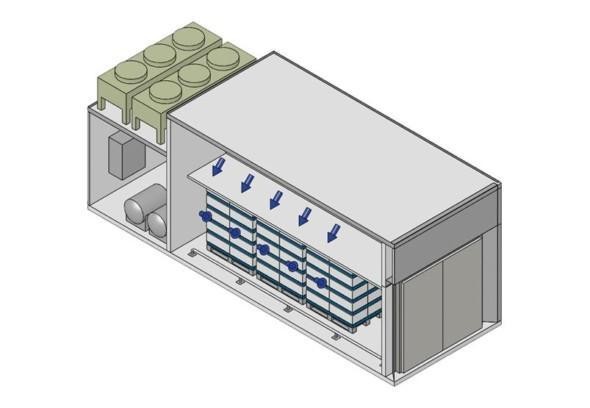

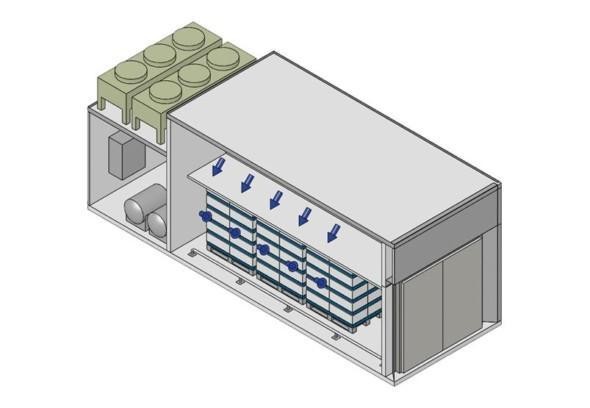

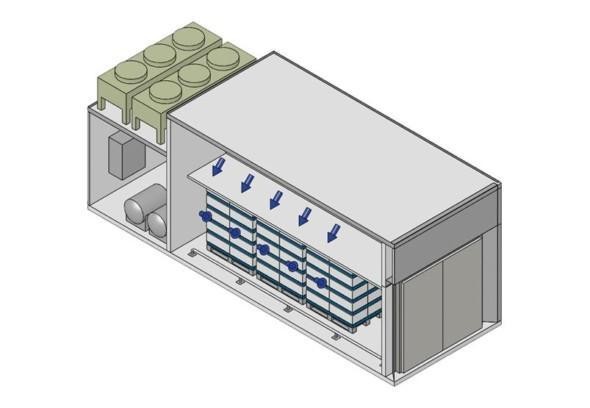

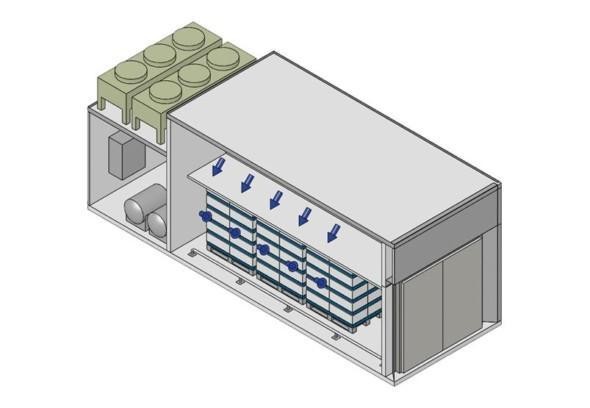

How the Finncold freezing systems work

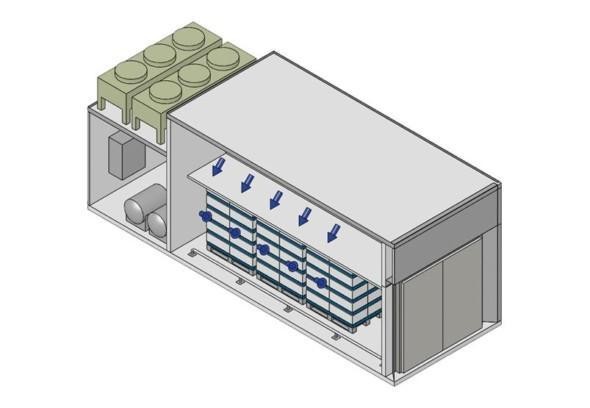

Our freezing rooms and freezing storage containers are built with so-called sandwich panels that are developed and approved for the food industry. Our freezing solutions are modular which allows them to be easily customized and fitted for different facilities and conditions.

The Finncold freezing tunnels utilize a powerful cooling and air circulation system. The circular airflow makes freezing fast and efficient, sparing the structure of the food products and keeping them fresh and high-quality.

Discover more related products and learn more about our stiffening systems and thawing systems.

What our customers say about us

I highly recommend Kometos and will certainly work with them also in the future.

– Jukka Orvola, Maintenance Manager, Kotivara Oy

Yes, you can use our freezing rooms for cold storage up to – 30 °C.

Our freezing rooms and containers are built with moisture-resistant and easily cleanable elements approved for the food industry. This guarantees hygiene during cooling and freezing. All internal surfaces of our thawing units have an antibacterial coating that provides lifelong protection against bacteria.

In addition, we follow the certified ISO 9001:2015 quality assurance program.

The faster the freezing, the higher the quality of the product. If the food product freezes slowly, it develops larger ice particles that break the structure of the product. Fast and efficient freezing keeps the quality better.