Fish processing plants

Custom facilities for hygienic and efficient fish processing

Finmodules fish processing plants provide a modular solution that’s ideal for processing fresh or frozen fish and crayfish, as well as storage and freezing.

👇 Learn more about our fish processing plants in the drop-down selector below and download a product card.

TECHNICAL INFORMATION

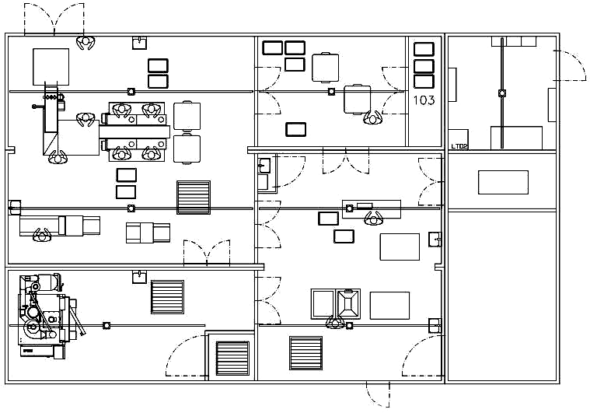

| Capacity | Fish processing 1,75 tn / day manufactured product.

Need for raw material 3,5 tn / day. |

| Number of modules | 4 pcs |

| Size approx. | 168 m2 |

Technical information

| Production | Fish alive to the factory, live weight 4 – 5 kgs.

Separate carcass, fillet, smoked products, cutlets and other fish products. Head, scales and fishbones separates to feed plant. |

| Capacity | Fish processing 1,75 tn / day manufactured product.

Need for raw material 3,5 tn / day. |

External connection

| Electricity | 400 V, 50 Hz, 400 A |

| Water | 70 – 100 l/min, 4 bar, 2” |

| Waste water | ø 110 mm |

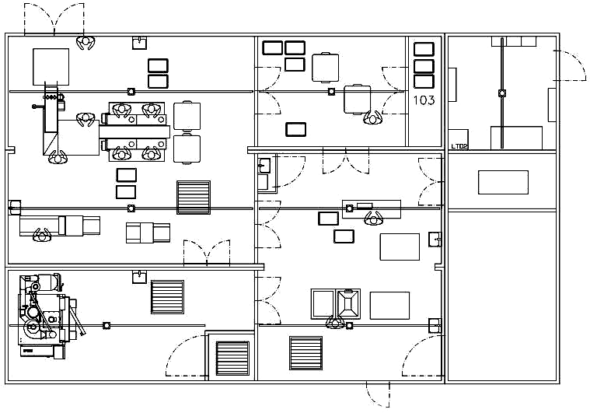

| Number of modules | 4 pcs |

| Size approx. | 168 m2 |

Fish processing plant units

- Receiving- / processing premises

- Heat treatment premises

- Packing premises

- Freezing tunnel

TECHNICAL INFORMATION

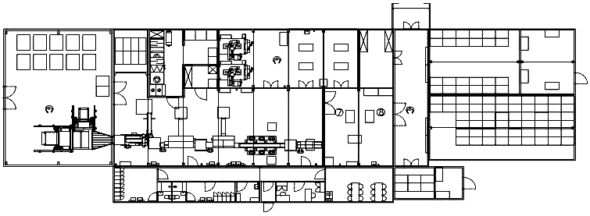

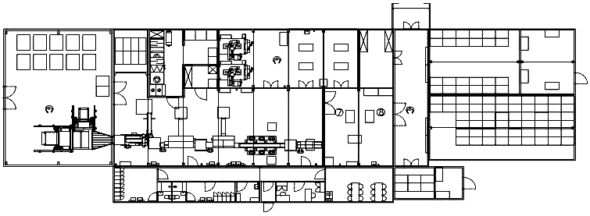

| Capacity | Fish processing 5 tn / day manufactured product.

Need for raw material 10 – 15 tn / day. |

| Number of modules | 15 pcs |

| Size approx. | 630 m2 |

Technical information

| Production | Fish alive to the factory, live weight 2 – 10 kgs.

Separate carcass, fillet, smoked products, cutlets and other fish products. Head, scales and fishbones separates to feed plant. |

| Capacity | Fish processing 5 tn / day manufactured product.

Need for raw material 10 – 15 tn / day. |

External connection

| Electricity | 400 V, 50 Hz, 400 A |

| Water | 70 – 100 l/min, 4 bar, 2” |

| Waste water | ø 110 mm |

| Number of modules | 15 pcs |

| Size approx. | 630 m2 |

Fish processing plant units

- Social premises

- Receiving premises

- Processing premises

- Heat treatment premises

- Packing premises

- Storage

- Freezing tunnel

- Freezing storage

- Cold storage

Custom solutions for fish processing

Energy-efficient solutions save costs

Hygienic and durable facilities

Why choose a Finmodules fish processing factory

Flexible solutions that adapt to changes in production

Thanks to their modular structure, Finmodules production facilities can be easily customized to different needs. Start operations with a smaller production plant, and when the capacity needs increase, new modules can be added flexibly.

Energy-efficient solutions that save your energy costs

Processing seafood has its unique challenges. Separate production facilities may be needed, which can result in big energy consumption. Kometos fish processing facilities use special technology to ensure energy-efficiency. And this means smaller energy bills for your business.

Durable production facilities even for the most demanding conditions

Finmodules production plants are built with durable and long-lasting materials. They withstand big temperature fluctuations, which makes them ideal for even the most demanding conditions. As our Norwegian customer said, “Even after twelve years, the walls are white and there’s no rust anywhere.”

What kind of products are Finmodules fish processing plants suitable for?

The possibilities are nearly endless. The modular structure allows the production plants to be equipped with a variety of machinery and facilities.

Examples of operations and processed products include:

- freshwater fish

- saltwater fish

- crayfish and shellfish

- fish cutting and slicing

- hot and cold smoking

- fish fillets and balls

- dried fish

- salted fish

- cooked fish products

Case: Norwegian Bugøynes Kongekrabben made significant savings with Kometos’ solution

Norwegian Bugøynes Kongekrabben produces large quantities of different fishes, fish eggs, and their main product, the red king crab. The red king crab especially posed some challenges for the production facilities.

The live crab needs to be stored in saltwater. Boiling the crab creates a lot of moisture which can be straining on the materials of the facilities. Usually, fish processing plants consist of multiple separate facilities, which can make the starting investment hefty.

But Kometos thought differently. We planned the fish production facilities in close collaboration with the client. The modular solution has stood the test of time and been in active use for years. The production plant cost a quarter of the price of a traditional fish processing system. And what’s more, the energy-efficient facilities save costs on the energy bill.

- Production capacity: 700 tons of seafood per year.

- The planning was carried out in close collaboration between Kometos and the client.

- The production facilities have been expanded as new needs have emerged. The new facilities include a module for fish farming, freezing, and a canteen.

We have expanded our premises several times to have more space for fish and king crab production. It wouldn’t have been possible without Kometos’s expertise, professional customer service, and regular contact with us.

– Öyvind Seipäjärvi, founder, Bugøynes Kongekrabben

We always tailor the solution to our client’s needs. Our modular facilities are easy to combine, customize and, if needed, scale and modify later. For instance, we can integrate production facilities, freezing, and thawing in one complete solution.

All our deliveries are so-called complete deliveries. It means that we build, equip and test the production facilities at our own factory before delivery. We handle the installation and train your staff to operate and maintain the facilities.

In the Finmodules product line, we also have custom solutions for meat processing.

Our modular production facilities are very versatile: they’re also suitable for processing dairy, berries, and juices. Contact us for a custom solution.