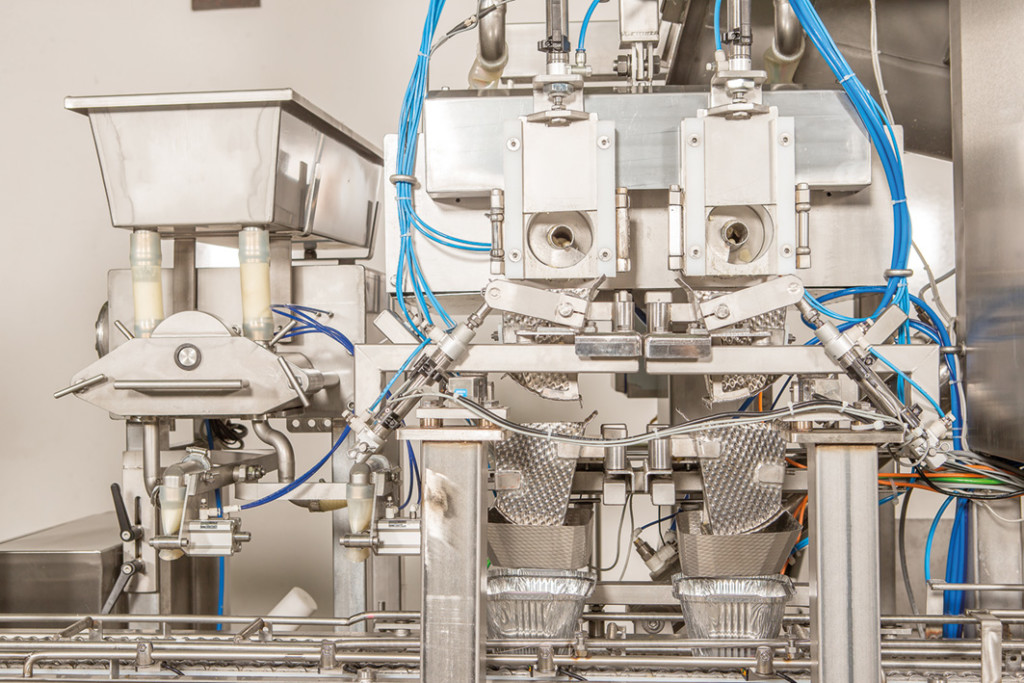

Finntray processing lines - automatic dosing systems and tray handling for ready meals

In our selection of food processing lines, you’ll find the right dosing system and food packaging line for different types of ready meals. The Finntray lines include tray dosing systems and food packaging machines designed by Kometos, as well as components provided by our industry-leading partners. Get the full tray handling system or only choose the parts you need.

👇 Learn more about our ready meal tray handling lines below and download a product card.

Or see our product videos:

Technical information

| Based on weight, depending on the product, 2 dosing units, 25 – 35 portions / minute |

| Based on volume, 1 – 3 dosing units, 30 – 90 portions / minute |

| Dosing range 50 – 500 gr, possibility also as multidosing |

Technical information

| Capacity | Depending on products 20 – 60 trays / min. |

| Denesters | Denester manually adjustable for M4 – M8 plastic trays. Styrofoam and cardboard trays optional. Empty tray buffer conveyor for up to 30 min production. |

| Construction | Fully food contact approved materials. AiSi 304 grade stainless steel and food contact approved plastic grades. |

| Control system | Plc Kometos / Siemens S7 with colour touch-screen operator interface. Remote access option for service connection. Data recording & collection software available as option. |

| IP Class | IP 65 |

| Power supply | 400 V/50 Hz, 16 A |

| Air supply | 6 bar, 50 l/min |

| Lay-out | Several lay-out options available |

| Dosing units solids | Weight based dosing or volume based dosing according to product. |

| Dosing units sauce | Volume based dosing for liquid or semi-liquid components that can be pumped. Multiple dosing heads (2 – 6) possible. Paint-function available. |

| Dosing units spices etc | Vibratory or rifle wheel depositors depending on product. |

Technical information

| Dosage size 200 – 500 gr |

| Capacity 200 – 300 portions / hour |

Technical information

| Capacity | Depending on the products, 200 – 300 trays / h, depends on the amount of pasta plate and sauce. |

| Length of the line | appr. 15 m. |

| Portion size | 200 – 500 gr. |

| Tray dispensers | Tray dispensers manually adjustable for cardboard- and plastic trays of different sizes. |

| Construction | Fully food contact approved materials. AiSi 304 grade stainless steel and food contact approved plastic grades. |

| Control system | Plc Kometos / Siemens S7 with colour touch-screen operator interface. Remote access option for service connection. |

| IP Class | IP 65 |

| Power supply | 400 V/50 hz, 16 A |

| Air supply | 6 bar, 50 l/min |

| Dosing units, solids | Weight-based or a volume based dosing according to the product. |

| Dosing units, sauce | Volume based dosing for sauce or semi-liquid components, that can be pumped. Also available with a weight correction function. |

| Dosing units | Vibrating dispenser for example grated cheese. |

| Product container volume | 200 l (2 pcs, if necessary) trolley dock with mixer and pipe outlet for pump. |

Technical information

| Products: Bags for food packing |

| Speed 4–8 bags/min. |

|

Actuator: Armrobots with sucker- and forked stick gripper, bag sealer |

Technical information

Bag handling- and boxing line

| Products |

Various powders and groats |

| Speed |

With collaboration function 4 bags / min., protected 8 bags / min. |

|

Actuator |

Armrobots with sucker- and forked stick gripper, bag sealer |

|

Control system |

Plc Kometos / Siemens S7 with colour display |

|

Electrical connection |

400V / 50 Hz / 16A |

|

Compressed air connection |

Min. 6 bar |

|

Accessories |

Checking scale, marking device, powder- or other dosing solutions |

Powder dispenser

| Products |

Various powders and groats |

|

Speed |

Up to 50 doses / min. |

|

Actuator |

Compressed air operation |

|

Accuracy |

Depending on the products up to +/- 1 gr. |

|

Volume of the product container |

Determined as needed |

|

Accessories |

Level monitoring sensor |

Efficient food tray handling minimizes waste and losses

Grow and customize the dosing line as your capacity grows

30+ years of experience in dosing and food packing

Why choose Finntray tray handling systems

Semiautomatic of fully automated tray handling line

Our tray handling systems are designed to fit our customers’ needs. The line can be either fully mechanized with automatic machinery and dosing units. Or if you want, integrate manual workstations in the line.

Dosing lines that grow with your production

We can modify and customize the ready meal tray handling line according to your requirements. When your production and capacity grow, the tray handling system grows along. We can add and integrate new units and machinery for added capacity or new seasonal products.

Our solutions meet the strict hygiene standards of the food industry

Sign up for a demo – we’ll test your product at our facility

Would you like to see how our dosing and packing line works for your product?

Deliver us the product you’d like to test and we’ll run it through our dosing and packaging machinery.

Finntray units are suitable for a variety of products

Ready meals

- Meals with meat or plant-based protein

- Pasta-based meals

- Rice-based meals

- Layered meals, like lasagna

- Soups

- Porridges

- Sauces and garnishes

Meat, poultry, fish, and seafood

- Meat and meat products, like sausages, meatballs, or cutlets

- Poultry and poultry products, like nuggets

- Fish, shellfish, and other seafood products, like fish fingers

Fruits, vegetables, seeds, and nuts

- Berries and fruit – fresh, dried, or powdered

- Vegetables – raw, cooked, sliced, or cubed

- Nuts and trail mixes

- Seeds and grain

- Spices and powders

Dosing and packing lines customized for your unique needs

The Finntray tray handling line is a flexible food dosing and packaging solution for both fresh and ready meals. You can choose a fully automated line, or if you need, integrate manual workstations into the line. We can equip the manual workstations with scales to determine the exact weight of the product – and minimize losses and food waste.

The final weight is adjusted by adding sauce with a Finntray sauce dispenser. If needed, other components, such as seasoning, spices, or cheese, can be dispensed to the trays with dosing equipment.

How the ready meal tray handling line works

The Finntray tray packaging line for ready meals is suitable for a variety of products, including rice, pasta, carrot, potato, meat, fish, and seafood as well as liquid components – all ingredients needed to make a ready meal. Our dosing and packing lines consist of weight-based and volume-based solid and liquid dispensers.

The dosing line integrates into tray handling equipment and tray closing machines to create the final packaged meal. The machinery is suitable for packing meals in trays of different sizes and shapes. We also offer adjustable denesters for several tray sizes.

In need of more spezialized units?

Make the line your own and customize it by integrating, for example, check weighers, metal detectors, x-ray equipment, or packing robots. Whatever units or parts you need, we deliver the complete solution. And if your needs change, we can easily change parts of the line.

Extensive maintenance for all Finntray lines

We offer extensive maintenance services to all our tray handling lines. Effective maintenance minimizes stops and pauses in your production. We also keep critical spare parts in stock. Get help and service fast; our maintenance arrives the next day, at the latest, at your facility.

What our customers say about us

“If there was one thing to highlight in particular, it would be the creativity of Kometos – they came up with the right solution to our challenge.”

– Ari Viitala, Production Manager, Linseed

Examples of our lines for dosing packaging of ready meals

Customer case: Lasagne dosing and packing line

We’ve developed a ready meal tray filling equipment and line specifically for lasagne products. The lasagne line consists of a tray dispenser, a trolley dock with mixer and pipe outlet for a pump, a Nestan 2-headed volume-based dispenser, a cobot, a closing and decking machine, a metal detector, conveyors, and a tray sealing device from our partner Tecnovac.

First, the Nestan dispenser doses the sauce in layers with lasagne sheets set by the cobot. The weight is balanced to the desired final weight by adding an adjusted amount of sauce for the last layer. A conveyor transfers the tray to a cheese dispenser if desired.

Next, the tray moves to a sealing machine that closes the tray either with a lid or film. The tray passes through a metal detector. Now the tray moves to a loading area to wait for packing.

Finally, after the tray handling line, the final product is transferred to a freezer tunnel and lastly, to cold storage. All done!

Customer case: Bag filling and packing line

Our bag filling line is a powerful complete solution for dosing and packing powders, liquids, or solid products into bags or pouches.

In the bag filling line, we employ robotics extensively. This allows us to free up the most monotonous tasks with poor ergonomics to cobots.

First, a cobot picks up the pouch with suction cups and opens it. Based on either weight or units, the desired amount of product is dispensed into the pouch. Next, the pouch moves to the checking scale where its weight is checked. If the weight doesn’t meet the set criteria, the pouch is rejected.

Finally, the pouch is closed and transferred to packing. The line is connected to a box conveyor where the pouches are packed into cardboard boxes either by staff or a cobot. We can also install a cobot to transfer the boxes to shipping or storage.

What does the process look like in practice? Watch our video.

The Finntray tray handling equipment can pack food into aluminum, cardboard, or plastic trays and boxes. The machinery is suitable for packing food into trays of different sizes and shapes. Our product line also includes adjustable denesters for several different tray sizes.

Yes, we can integrate manual workstations into the line for the packaging of ready meals. You can improve efficiency by automating the more monotonous manual steps, and this way free up the workforce for the more demanding tasks in the packing line.

We can always customize the tray handling line for your needs. Add machines and units, such as dispensers, tray closing machines, or a metal detector. And of course, if needed, add manual workstations.

Yes, on top of complete solutions we also provide individual dosing and tray handling units and machines. Learn more about dosing units here and tray handling units here.