Dosing units

Finntray dosing dispensers for the food industry

Our product range includes various ready-to-eat food dispensers and dosing units. All our food dosing systems meet the strictest quality and hygiene requirements of the food processing industry.

The Finntray dosing dispensers are designed to minimize waste in production and improve the whole production process. Our in-house design and manufacturing allow us to provide customers with standard products as well as individually customized solutions.

👇 Learn more about our models and food dosing machines in the drop-down selector below and download a product card for specific product below the technical information.

Or see our product videos:

Technical information

| Volume-based piston dispenser, dosing range 50-300 ml or 100-500 ml / cylinder |

| In dosing cylinder servo motor control |

| Setting values are set from the touch screen, 99 recipe memory places |

| Accuracy ˂ 1%, if the product has max. 2 mm solid particles |

Technical information

| Products | Liquid products like soups, sauces, mayonnaise based salads, jams, honey, water, oil etc. Products can contain solid particles Ø 3 mm (product-/model specific feature). |

| Dosing range | According to cylinder diameter and piston stroke from 20-400 cc per dosing cylinder. |

| Dosing accuracy | > 99 from target weight %. Depending on product characteristics. Viscocity 500-4000 (cP). |

| Speed | Up to 60 cycles per minute depending on product and volume. |

| Actuator | Electric servo motor |

| Control system | Siemens plc with colour display. 99 different recipies can be pre-programmed. Multiple dosing possible. Counter for portions. |

| Applications | Tray filling lines, bottle and jar filling lines and dosing of individual products. |

| Product container volume | 30-200 L, level monitoring sensor. |

| Accessories | Stirring tool, paint-function for dosing, heating for product container, product transfer pump, larger dosage size |

Technical information

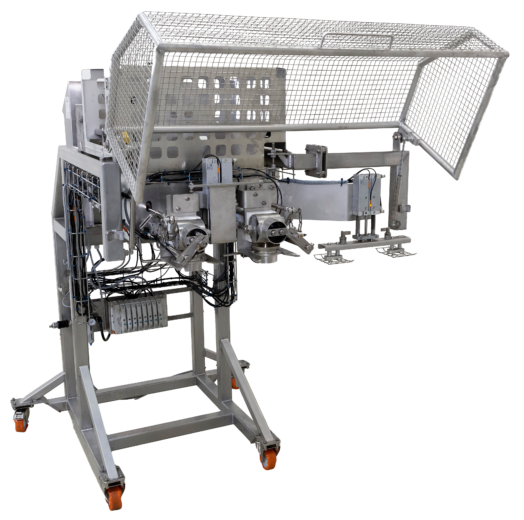

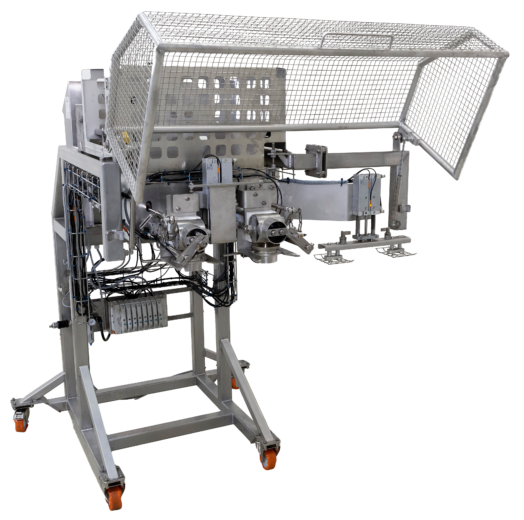

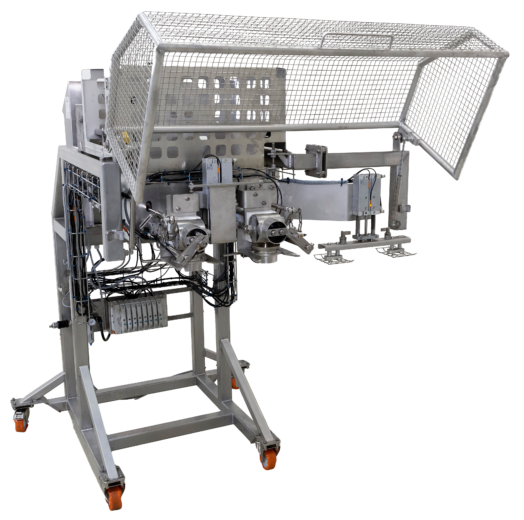

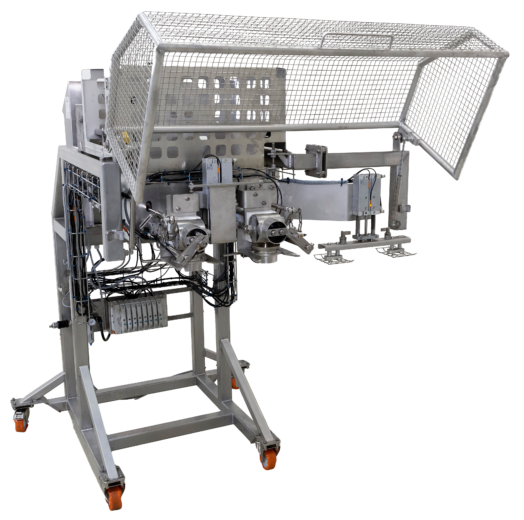

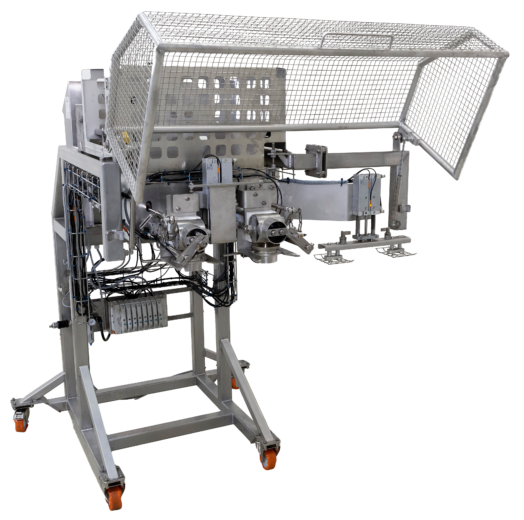

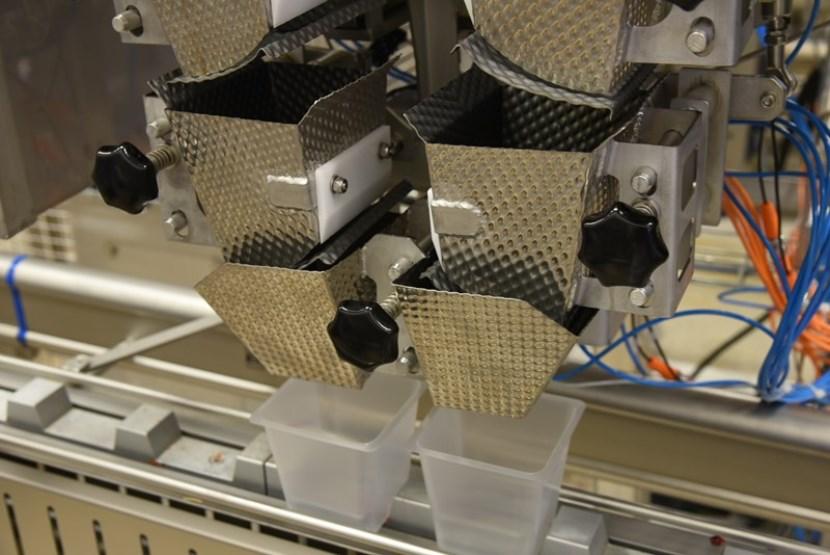

| Products to be dispensed through the drop funnel into a tray |

| Gentle on products |

| Fast and accurate dosing |

| Quick and easy product changes |

Technical information

| Products | Boiled or raw vegetable or root crop cubes, boiled pasta and rice, raw or baked meat cubes, potato slices and strips. |

| Dosing range | 2 x 50-500 g depending on product |

| Dosing accuracy | ± 10 g ≥ 150 g package, ± 5 g ≤ 150 g package |

| Speed | 30-60 portions / minute, 1-2 headed dosing |

| Actuator | Electric servo motor |

| Control system | Kometos, with Siemens plc colour display. Dosage size is set from the control panel. Multiple dosing possible |

| Applications | Enables to pre-programme 99 different product recipes. |

| Product container volume | 50-200 L |

| Accessories | Bin cart lift for 200 L bin cart |

Technical information

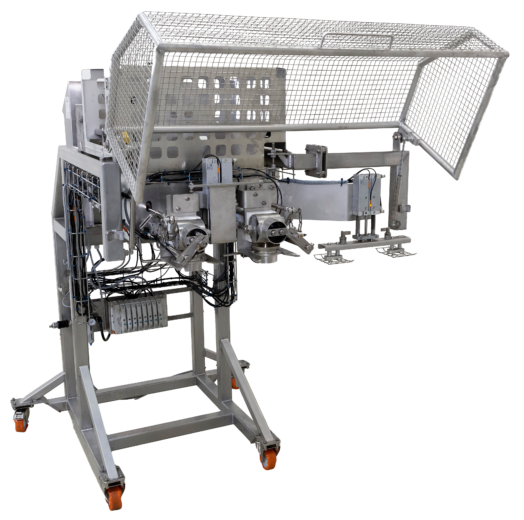

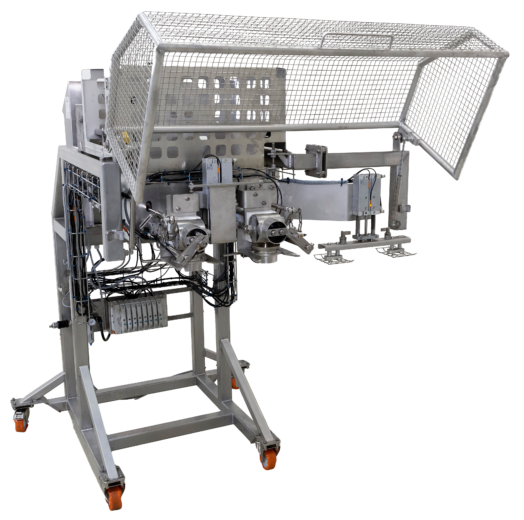

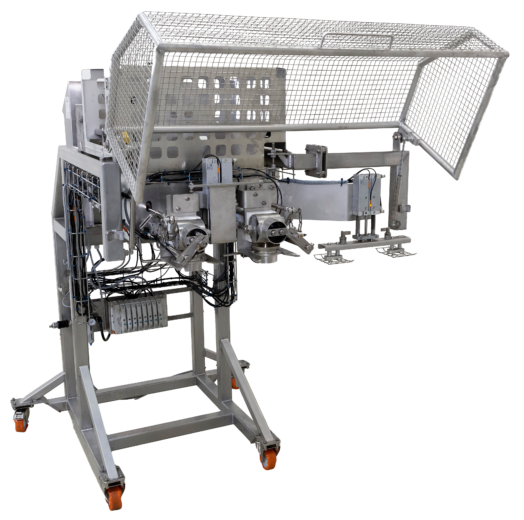

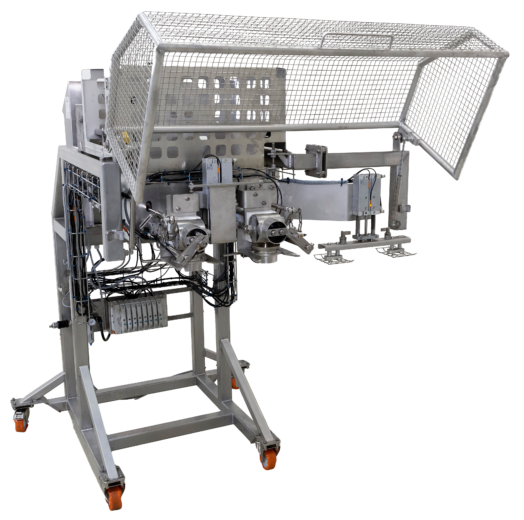

| Products to be dispensed through the drop funnel into a tray |

| Gentle on products |

| Fast and accurate dosing |

| Quick and easy product changes |

Technical information

| Products | Boiled or raw vegetable or root crop cubes, boiled pasta and rice, raw or baked meat cubes, potato slices and strips. |

| Dosing range | 3 x 50-500 g depending on product |

| Dosing accuracy | ± 10 g ≥ 150 g package, ± 5 g ≤ 150 g packag |

| Speed | 30-90 portions / minute, 1-3 headed dosing |

| Actuator | Electric servo motor |

| Control system | Kometos, with Siemens plc colour display. Dosage size is set from the control panel. Multiple dosing possible. |

| Applications | Enables to pre-programme 99 different product recipes. |

| Product container volume | 50-200 L |

| Accessories | Bin cart lift for 200 L bin cart |

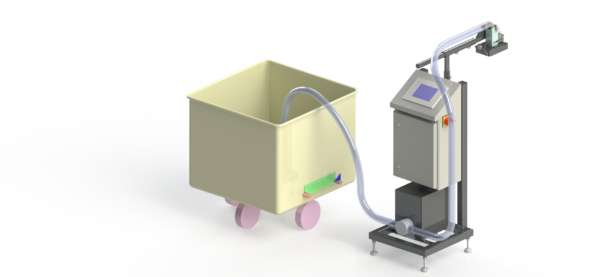

Technical information

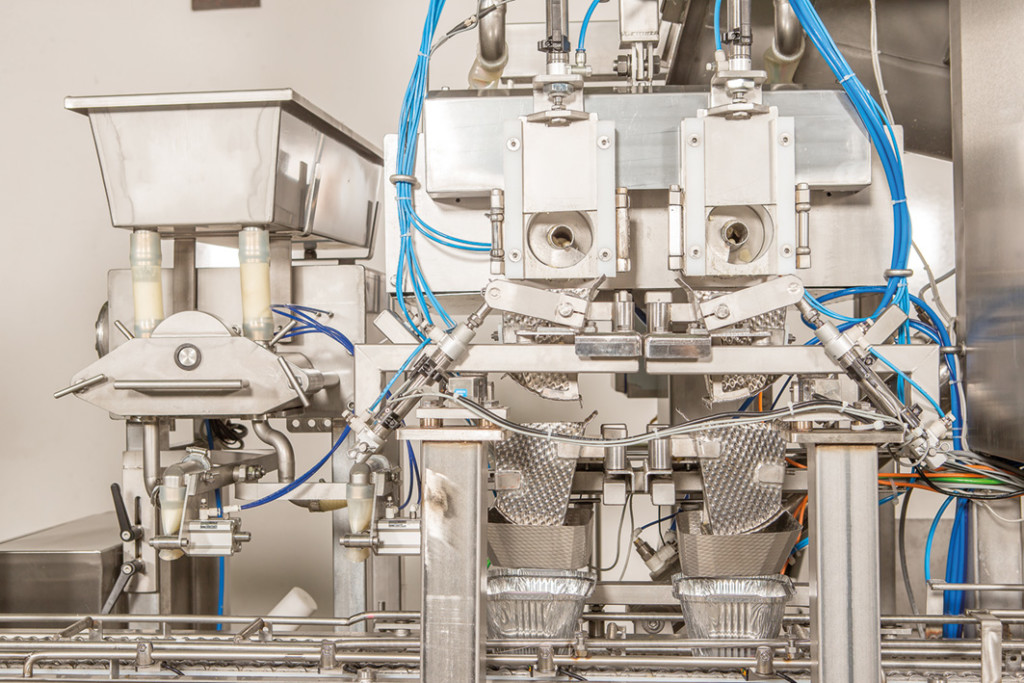

| Products to be dispensed through the drop funnel into a tray |

| Gentle on products |

| Fast and accurate dosing |

| Quick and easy product changes |

Technical information

| Products | Frozen, boiled or raw vegetable or root crop cubes, boiled pasta and rice, noodles, pasta and vegetable salads, salad, raw or baked meat cubes or cuts, different convenience food components. |

| Dosing range | 2 x 50-500 g (2 dosing units). Dosage size is set in grams from the control panel. |

| Dosing accuracy | ± 10 g ≥ 150 g package, ± 5 g ≤ 150 g package, depending on product homogeneity and particle size. |

| Speed | 30 doses / minute |

| Actuator | Electric servo motor |

| Control system | Kometos, with Siemens plc colour display. Dosage size is set from the control panel. Multiple dosing possible. |

| Applications | Enables to pre-programme 99 different product recipes. |

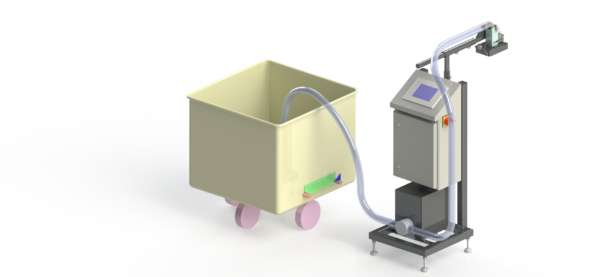

| Product container volume | 200 L, water hydraulic tipping into washing position. |

| Accessories | Bin cart lift for 200 L bin cart. Mass transfer pump directly from the bin cart. |

Technical information

| Round components according to the desired number of pieces for dosing |

Technical information

| Products | Meatballs, fish balls and vegetable balls (round components). |

| Dosing range | 3-8 pieces / dosing head. Dosage size is set in pieces from the control panel. |

| Dosing accuracy | 98 % |

| Speed | 30-40 portions / minute |

| Actuator | Electric servo motor / pneumatic. |

| Control system | Plc Kometos / Siemens S7 colour display. |

| Product container volume | 60 L = Transbox |

| Accessories | Bin cart of transbox lift / pouring device. |

Technical information

|

Products: meatballs, nuggets, small sausages, meat cubes (chilled), other free flowing and slightly sticky products |

|

Inclined elevator conveyor |

|

Multihead weigher with 12 heads |

Technical information

|

Products: meatballs, nuggets, small sausages, meat cubes (chilled), other free flowing and slightly sticky products |

|

Inclined elevator conveyor |

|

Multihead weigher with 12 heads |

|

Multihead weigher platform with washing facility for weigher parts |

|

Distribution unit for 3 x 4 format |

|

Thermoformer unit 10 cycles per minute with gas flushing |

|

Labelling unit, 3 lanes |

|

X-ray unit |

|

Special models for salads |

|

Easy-to-use operating interface |

|

Counting software available |

|

Production data collection |

|

IP 65 |

Technical information

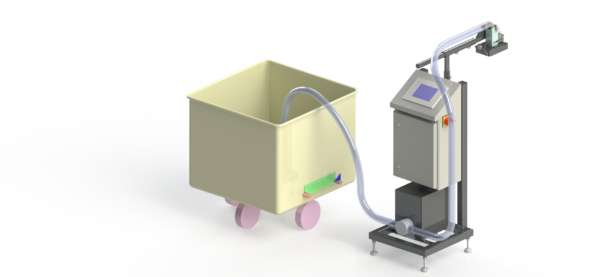

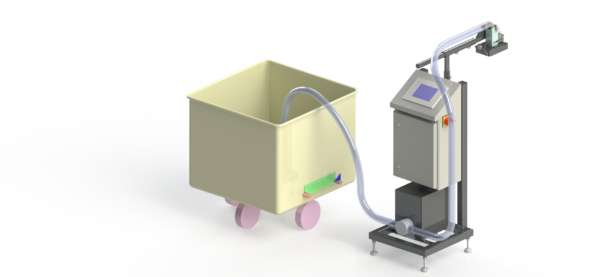

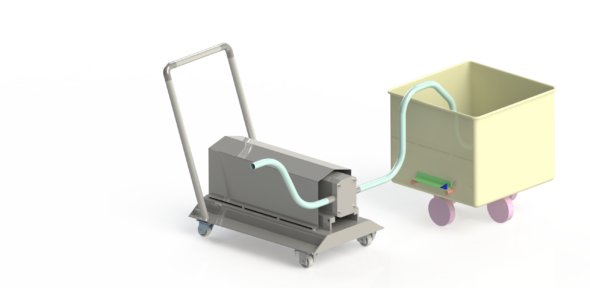

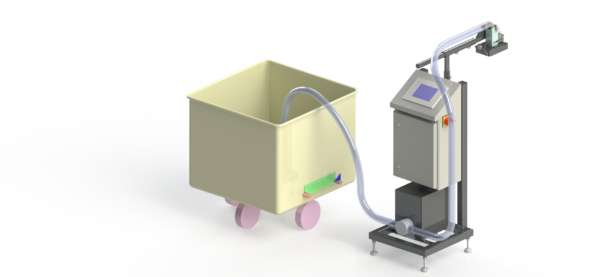

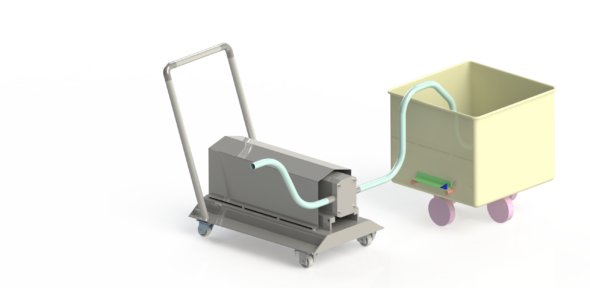

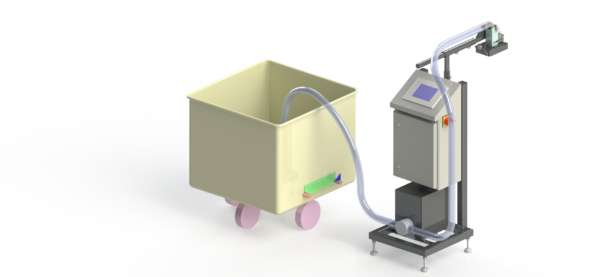

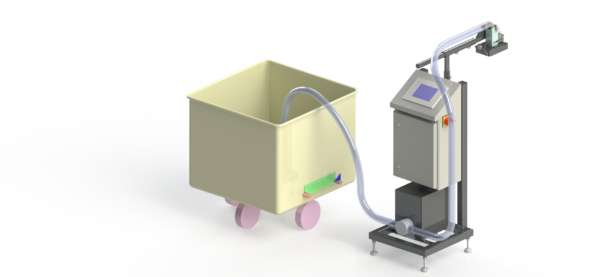

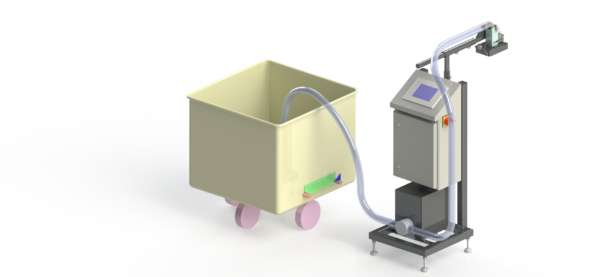

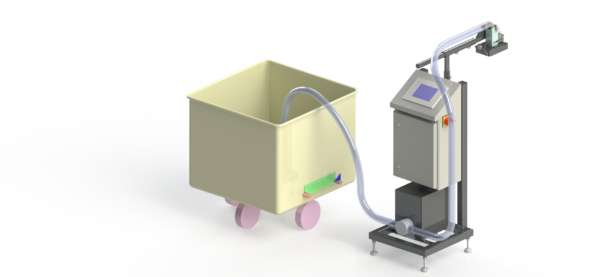

| For liquid products with viscosity < 4000 cP such as soups, sauces, marinades, kisels, honey, water, oil etc. |

| Accuracy < 1% depending on the product characteristics |

Technical information

| Products | Liquid products as soups, sauces, marinades, kisels, honey, water, oil etc. |

| Max. flow and particle size | 7-365 l / min., 3-13 mm |

| Dosing accuracy | < 1% depending on the product characteristics |

| Speed | Up to 60 cycles per minute depending on the product and dosage amount |

| Structure | Rubber wing pump, stainless steel, incl. 1 pc dosing head. |

| Control system | Siemens PLC with colour display. 99 different recipies can be pre-programmed. Counter for portions. Ability to communicate with a line or other external device. |

| Applications | Box lines, deep drawing lines and other packaging filling lines and corresponding applications. |

| Accessories | Weight bridge, different dosing head solutions, painting function. |

Technical information

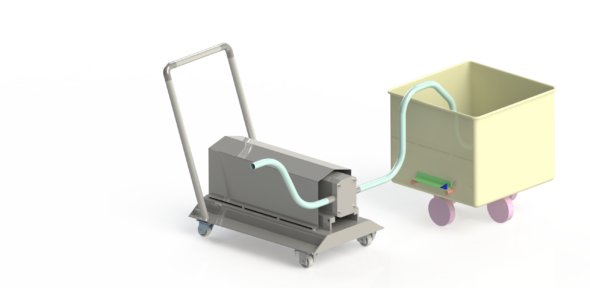

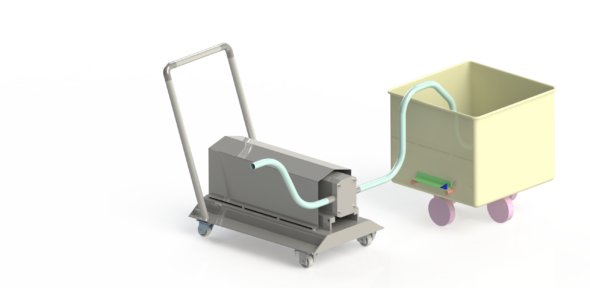

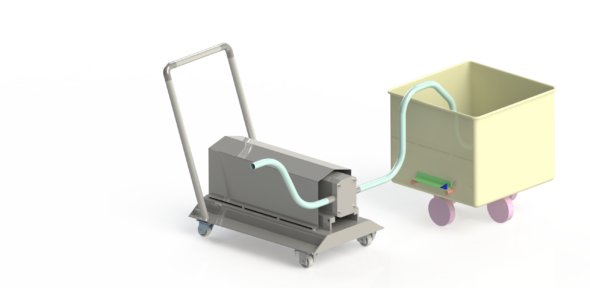

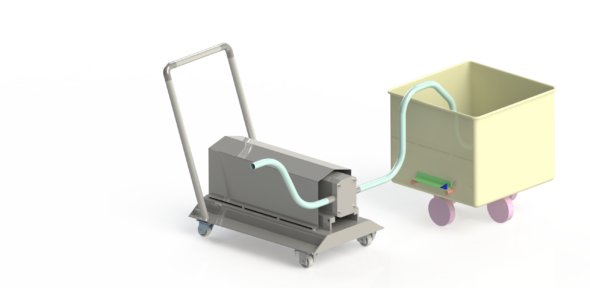

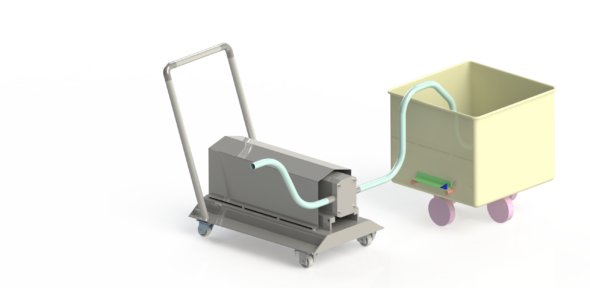

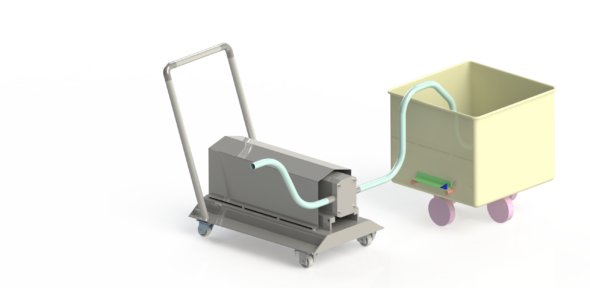

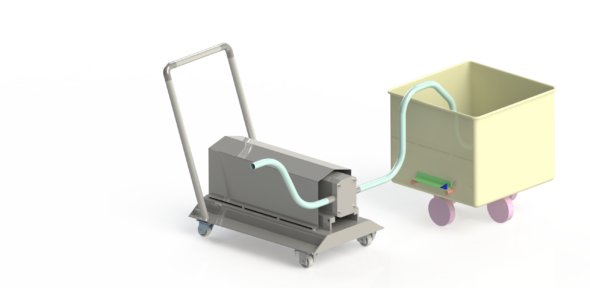

| For liquid and thick products with viscosity up to 8.000.000 cP such as jams, mayonnaise-based salads, oils, soured whole milk, yoghurts, curds, porridges etc. |

| Accuracy < 1% depending on the product characteristics |

Technical information

| Products | Liquid and thick products such as jams, mayonnaise-based salads, oils, soured whole milk, yoghurts, curds, porridges etc.. |

| Max. flow and particle size | 255 000 l / h, 13 – 100 mm |

| Dosing accuracy | < 1% depending on the product characteristics |

| Speed | Up to 50 cycles per minute depending on the product and dosage amount |

| Structure | Cine pump, stainless steel |

| Control system | Operating switches in Aisi 304 -housing. In dosing use Siemens PLC with color display. |

| Applications | Transfer of materials between processes, filling of tanks, in dosing use filling of packages etc. |

| Accessories | Weight bridge, dosing head solutions, surface guard sensing, feed hopper, CIP |

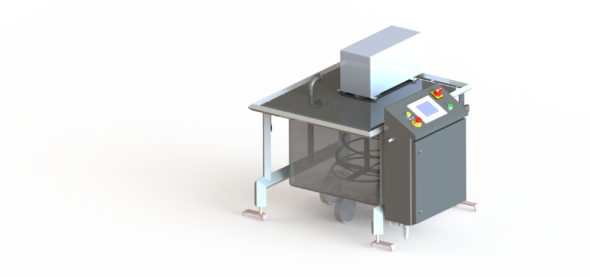

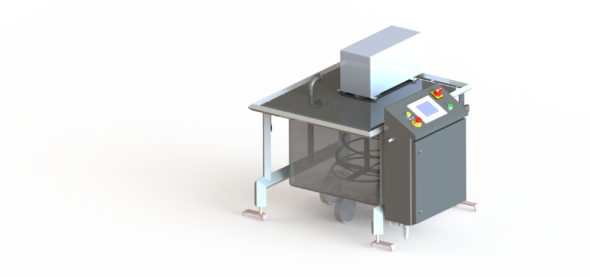

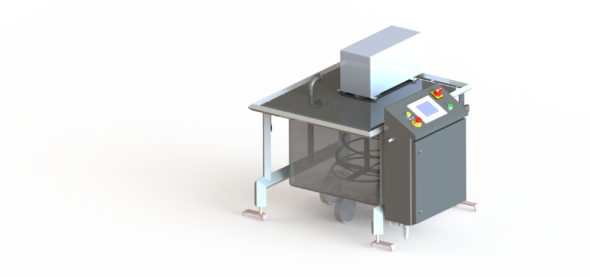

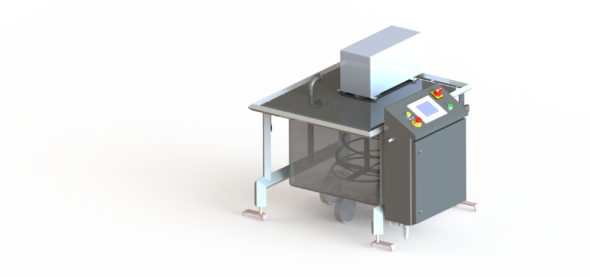

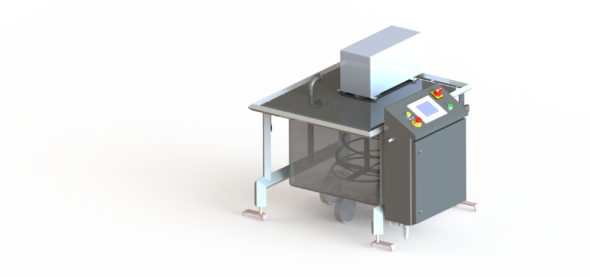

Technical information

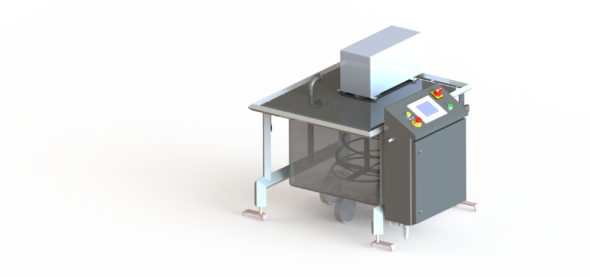

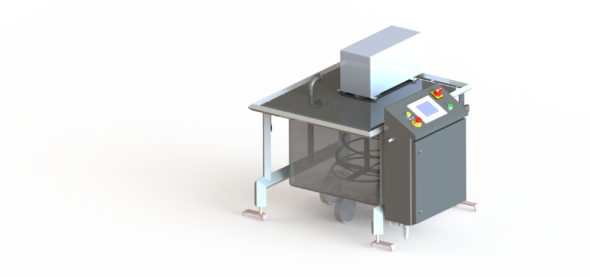

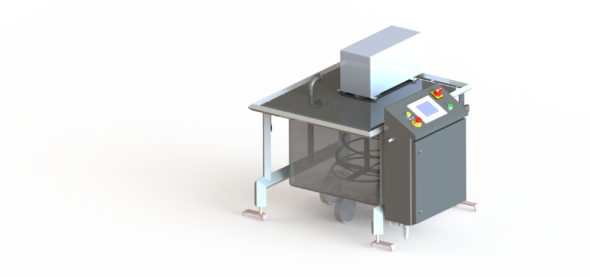

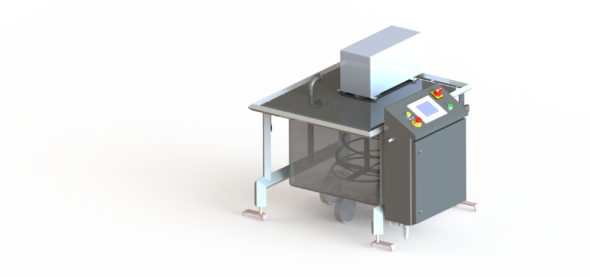

| For liquid and thick products such as soups, sauces, marinades, kisels, honey, water, oil, jams, mayonnaise-based salads, oils, soured whole milk, yoghurts, curds, porridges etc. |

| Speed up to 60 cycles per minute, or according to material requirements |

Technical information

| Products | Liquid and thick products such as jams, mayonnaise-based salads, oils, soured whole milk, yoghurts, curds, porridges etc.. |

| Speed | Up to 60 cycles per minute, or according to material requirements |

| Mixing time control | Continuous or time-set |

| Control system | Operating switches in stainless steel enclosure |

| Structure | Stainless steel |

| Pipe connection | SMS food-grade fittings, size according to material requirements |

| Applications | Mixing variety of materials, integration capability to dosing and trasfer pumps |

| Accessories | Various mixing tools for different materials |

Efficient food dosing minimizes waste and losses

Adjust the dosing line to match growth or seasonal products

30+ years of experience in the food processing industry

Why choose Finntray food dosing systems

Optimized dosing minimizes waste and losses

The ingredients in the ready-to-eat food industry can be expensive. That’s why it’s important to minimize waste in food processing and ensure the flexibility and adaptability of the machinery. The Finntray dosing system minimizes losses.

The dosing system grows with your production

Start with the basic line and introduce new dosing units as your production grows. We can integrate different technology into the line, including manual workstations for manual dosing.

Flexible dosing lines easily adapted to product changes

The food processing industry changes seasons and products fast. The Finntray dosing line is flexible and it can be adjusted to accommodate new products even on a tight schedule.

Quick pay-back time

The pay-back time for a single dosing unit should be less than two years. One factor to take into account in the calculation is how much automation can free up human resources for other, more demanding tasks. The Finntray dosing systems pays back the investment quickly.

Meets the strict hygiene standards of the food industry

All our food dosing systems meet the strictest quality and hygiene requirements of the food industry. To maintain good hygiene, all our dosing lines and machines are easy to clean.

Extensive maintenance for all our dosing lines

We offer extensive maintenance services to all our dosing lines. With proper maintenance, we can minimize stops and pauses in your production. We also keep critical spare parts in stock. We react fast to service calls; our maintenance arrives the next day, at the latest, at your facility.

Sign up for a demo – we’ll test your product at our facility

Would you like to see how our dosing and packing line works for your product?

Deliver us the product you’d like to test and we’ll run it through our dosing and packaging machinery.

Finntray units are suitable for a variety of products

Ready meals

- Meals with meat or plant-based protein

- Pasta-based meals

- Rice-based meals

- Layered meals, like lasagna

- Soups

- Porridges

- Sauces and garnishes

Meat, poultry, fish, and seafood

- Meat and meat products, like sausages, meatballs, or cutlets

- Poultry and poultry products, like nuggets

- Fish, shellfish, and other seafood products, like fish fingers

Fruits, vegetables, seeds, and nuts

- Berries and fruit – fresh, dried, or powdered

- Vegetables – raw, cooked, sliced, or cubed

- Nuts and trail mixes

- Seeds and grain

- Spices and powders

How the Finntray dosing lines work

Our food dosing systems are designed for dosing ready-to-eat foods and meals. The dosing lines are suitable for different packing materials: the line doses and packs food in aluminum, cardboard, and plastic boxes and trays.

The automatic dosing systems include food dispensers designed to dispense and dose both liquid and solid foods, as well as mixtures of both. After dosing, liquid components, such as sauce or cream, can be added to create the final ready-to-eat meal. The Finntray dosing line is also suitable for preparing soups.

Food dosing systems customized for your needs

We can integrate several parts and units into the Finntray automatic dosing systems. Get your production automation started with the basic dosing line – as your production grows, we’ll add more units to your line.

The Finntray food dosing systems include:

- tray dispensers

- weight-based and volume-based food dispensers

- solid food dispensers (based on unit calculation)

- liquid food dispensers

- conveyors

- tray sealing devices provided by our partner Tecnovac

What our customers say about our dosing unit

With Kometos, installation was very smooth, lasting only one workday. The doser functioned immediately as expected and its operation fits in the routine. The solution offered by Kometos also had the best price/quality ratio.

– Pekka Honkaranta, CEO, Domretor Oy

The Finntray dosing line can dose and pack food into aluminum, cardboard, or plastic trays and boxes. The food dosing system is suitable for trays of different sizes and shapes. Our product line also includes adjustable denesters for several different tray sizes.

Yes, we can integrate manual workstations into the dosing line. You can improve the efficiency by automating the more monotonous manual steps, and this way free up the workforce for the more demanding tasks in the line.

We manufacture most of the food dosing machines and dispensers. Our dosing lines also include units provided by our partners, such as Tecnovac’s tray sealing machines. We deliver the complete system and line to our customers and test it first in our production facility.