Efficient food thawing process keeps the flavours, while minimizing losses

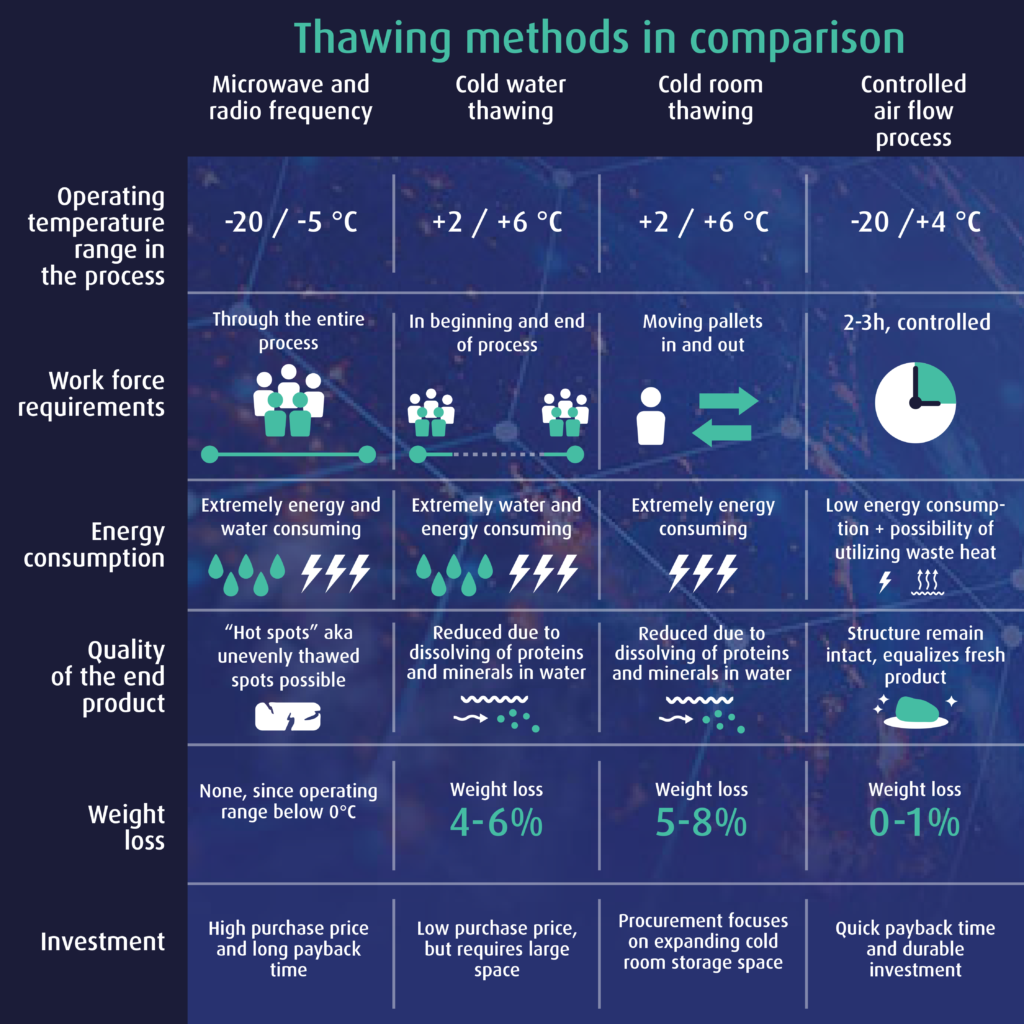

In the food industry, choosing the right thawing method is important both in terms of product quality, energy consumption, and labour costs. But which method of thawing food is correct? A smooth and controlled thawing process which doesn’t break the structure of food, is a key to guarantee a tasty food.

In the table above, we have compared different thawing processes and their efficiency. Defrosting of meat, fish and vegetables should be smooth, controlled, and not breaking the structure of food. Breaking the cell structure in the thawing process reduces the quality of the product and increases losses in the weight of the product.

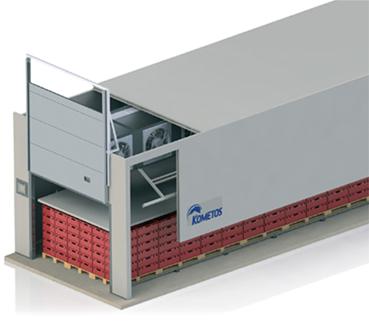

Kometos Finncold thawing system is the only controlled thawing method on the market. Finncold thawing system allows the thawing temperature to be adjusted according to the product’s properties without breaking the product’s structure.

Finncold thawing system is suitable for controlled thawing process of all frozen foods. Products defrosted using the Finncold thawing method are as good as fresh food, because the surface temperature of the product to be defrosted does not rise above the set target temperature.

Caviar, for example, is very sensitive and its quality deteriorates already when the process temperature is 6-7 degrees Celsius. Chicken, pork, and beef, on the other hand, withstand temperature fluctuations in the processing space much better, but with an optimal thawing process, the quality of these raw materials can also be improved.

Food thawing process using air flow minimizes losses

Finncold thawing process utilizes heat, controlled air flow, cryogenics, humidity, and the “ice bank” formed by the frozen food products. Loss of raw material i.e., escape of liquids and evaporation is minimized to less than one percent. This has a positive effect on the payback time of the thawing system, leave alone the fact that fast thawing and an efficient thawing method helps better planning of the production.

The temperature range of the thawing process is -20/+4 °C and may be in special cases even higher. With Finncold thawing system the final temperature of the products to be defrosted can be brought to +1/+2 °C. The CEO of Kometos, Raimo Niemi, says:

With our thawing solution, it is possible to bring the final temperature of the product close to zero, which means that the surface cells remain unopened, and the product does not drip nor ripen. The product quality, i.e., colour, final temperature and taste is also consistent. The end result of the thawing process is a high-quality product with minimal loss.”

Hygienic, easy-to-use, and safe thawing process

Finncold thawing method is filled by batch principle. If necessary, the products can be prepared in the thawing unit in advance determining the start time of the thawing process. In this case, the system operates as a frozen storage until the start of the thawing process according to the pre-set schedule.

Only indoor air is used in the thawing process ensuring it is completely hygienic and safe method for thawing food. Controlled temperature enables controlled thawing process for all frozen foods, from caviar to turkey, and for 10-15 pallets of frozen products the thawing method requires 2-3 manhours.

Cooling equipment enables scheduled thawing process for max. 48 hours at a time. When the target temperature for the product has been reached, the thawing system automatically switches to storage mode, keeping the food at the desired constant temperature.

The cold storage space ensures the right temperature of the raw materials for the production processes throughout the day. The antibacterial coating on the inner surface of the thawing unit also provides lifelong protection against bacteria.

INTERESTED? CONTACT US FOR DEMO: