Improved efficiency for the food industry with custom dosing units

The shorter life cycle of convenience food products requires flexibility and versatility from the dosing equipment of the food industry. Good production control, combined with versatile dosing lines, guarantees production efficiency and a short payback period of the dosing equipment.

Product development in the ready meal industry has increased worldwide. The surge in the popularity of ready-made meals and the diversification of products on offer is visible in the frozen food section in stores, such as the prevalence of vegetarian and vegan dishes, expanded choice of frozen foods, and an increase in high-quality restaurant-grade portions. The convenience food industry is growing at an annual rate of 10%.

Dosing units need to adapt to the changing seasons of the convenient food industry

With the seasonal nature of products, rapid product development, and food trends, the life cycle of individual products has become shorter. In production, the life cycle of food products should correspond with the investments in dosing equipment: more versatile lines are developed and installed to allow more flexibility, and automation and robotics are introduced where appropriate.

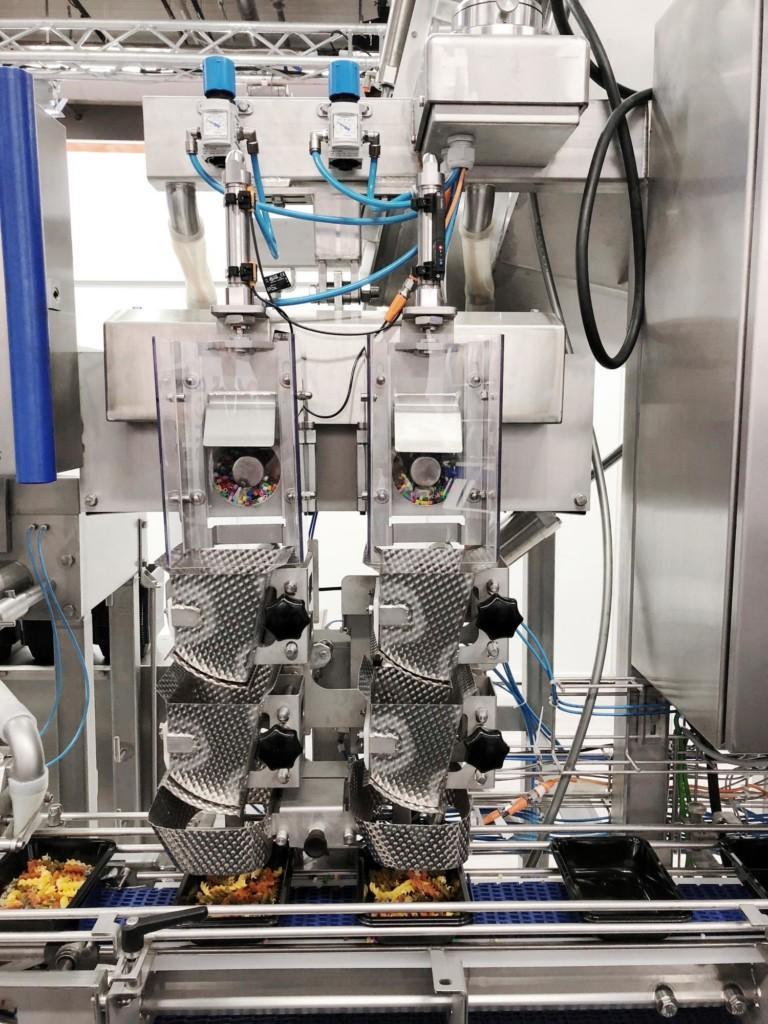

To allow cost-efficient product changes for the food industry, Kometos dosing machines stand out with versatility, durability, and easy maintenance.

We compiled a list of things to consider when you’re making an investment decision about dosing units and systems. Here are the seven key points:

1. Payback period of the dispensing system

In the food industry, the payback period of an individual dosing machine should be less than two years. It’s advisable to take this into account in the design of the dispensing equipment and dosing lines to make sure the solutions are cost-effective. When calculating the payback period, you should consider, for example, how many people will be freed up for other tasks after mechanization.

2. Dispensing efficiency and accuracy in convenience food production

The production control system should be of high quality and well-planned to ensure accurate dispensing, quick and easy product changes, machine cleaning, while maintaining production efficiency.

3. Versatility of dosing lines in the food industry

With Kometos equipment, the client can start by investing in the basic line and then develop the dosing line as needed for more versatility by combining technology and manual dosing.

4. Food hygiene

In food production plants, the longer shelf life of convenience foods is based on the entire manufacturing process and good hygiene. Good food hygiene during production prevents financial losses for the manufacturer as well as the consumer.

5. Valuable materials and production flexibility in the food industry

The materials of convenience food are valuable. Along with good food hygiene, it’s important to keep wastage to a minimum and ensure production flexibility.

6. Quick product changes of the dosing units

The production control system should be of high quality and well-designed so that product changes and cleaning of machines can be carried out easily while maintaining production efficiency.

Each Kometos dosing machine has a control system. All dosing units can also be connected to the control system of the overall line and managed as a whole.

7. How easy the dosing equipment is to clean and maintain

Fast product changes call for efficient and fast cleaning of the dispensing equipment and for durable and easy-to-maintain machines.