The Role of Dosing Units in Large-Scale Ready Meal Production

Dosing units are essential in large-scale ready meal production, ensuring precise portioning of ingredients to maintain consistency, quality, and efficiency.

By automating the measurement and dispensing process, these units help deliver uniform taste and texture in every meal. Accurate dosing minimizes ingredient waste, leading to cost savings and optimized production.

However, handling various food consistencies—liquids, semi-solids, and solids—poses challenges in maintaining high-speed, precise dosing.

This article explores the technical aspects of dosing units and offers guidance on selecting the right unit to meet specific production needs.

What Are Dosing Units?

Dosing units are like the master chefs of large-scale meal production—precise, efficient, and never off their game. They ensure every portion is just right, so your ready meals taste the same from batch to batch.

Why dosing units matter:

- Precision at its best – No more guesswork! These units measure and dispense exact ingredient portions for consistent meal quality.

- Efficiency booster – Automation replaces manual labor, speeding up production while reducing human errors.

- Cost-cutting champion – Less waste, better resource management, and lower production costs.

- Hygiene hero – Designed for contamination-free ingredient handling, ensuring compliance with food safety standards.

Dosing units handle a mix of ingredients—pasta, rice, veggies, and sauces—each with its own quirks. Thanks to seamless integration with automated tray-filling lines, they keep everything portioned perfectly, even at high speeds.

Beyond measuring and dispensing, dosing units optimize ingredient placement, helping manufacturers maintain both efficiency and product standardization. This means better consistency, smoother operations, and meals that always hit the mark.

Accurate dosing units improve both production efficiency and meal quality while reducing waste.

Breaking Down the Technical Details of Dosing Units

Dosing Range and Accuracy

The dosing range defines the minimum and maximum quantity a unit can dispense per cycle. A unit with a flexible dosing range can handle different portion sizes without needing frequent adjustments or equipment changes. This is critical in large-scale food production, where multiple recipes require precise ingredient portions.

Accuracy in dosing directly affects portion consistency and ingredient usage. Inconsistent dosing leads to overfilled or underfilled portions, impacting both cost and product quality.

Overfilling increases raw material waste, raising production costs. Underfilling risks regulatory non-compliance and customer dissatisfaction because of short-weighted portions.

Precision dosing ensures compliance with food industry regulations while maintaining brand reputation. Many dosing units achieve accuracy levels of ±1% of the target weight, though this varies based on technology:

- Volumetric dosing measures ingredients by volume, making it suitable for free-flowing materials but less precise for products with density variations.

- Gravimetric dosing measures by weight, providing higher accuracy, especially for ingredients with inconsistent densities.

Choosing the right dosing technology depends on your ingredient properties and required precision. A highly accurate dosing system reduces material loss, improves cost efficiency, and delivers consistent meal portions to your customers.

High-precision dosing controls waste, ensures compliance, and maintains portion consistency.

Speed and Throughput Efficiency

The number of dosing cycles per minute directly impacts overall output, making high-speed units important for maintaining production targets. Faster dosing reduces bottlenecks, ensuring that ingredients are dispensed at a rate that matches the rest of the processing line.

The number of dosing cycles per minute directly impacts overall output, making high-speed units important for maintaining production targets. Faster dosing reduces bottlenecks, ensuring that ingredients are dispensed at a rate that matches the rest of the processing line.

However, increasing speed comes with challenges. Faster dosing can compromise accuracy, especially when handling small portion sizes or complex formulations.

To maintain precision, advanced control systems such as servo-driven actuators and real-time weight monitoring are often necessary. These technologies adjust dosing parameters dynamically, compensating for variations in ingredient flow and ensuring consistency.

Several factors influence dosing speed, including:

- Ingredient type – Granular, powdered, and liquid ingredients behave differently during dosing, requiring tailored dispensing mechanisms.

- Viscosity – Thick sauces or pastes flow more slowly than thin liquids, limiting the achievable dosing rate.

- Portion size – Larger portions take longer to dispense, affecting the overall cycle time per dose.

- Nozzle and valve design – Optimized components reduce flow restrictions and ensure faster, more consistent dispensing.

To achieve both speed and accuracy, manufacturers have to balance these elements and select dosing units that align with their specific production requirements.

Throughput efficiency in dosing units determines how well a production line meets its output goals.

Viscosity Handling and Ingredient Compatibility

Dosing units have to accommodate liquids, semi-solids, and solid ingredients without compromising accuracy or efficiency. Each texture presents unique challenges, making specialized dosing mechanisms essential.

For thick sauces, purees, and chunkier ingredients like diced vegetables or rice, dosing units rely on specific design features to maintain consistency and prevent clogging. Key mechanisms include:

- Adjustable nozzles that control flow width and ensure even distribution.

- Pressure-regulated pumps to maintain steady ingredient flow, especially for viscous or particulate-heavy foods.

- Auger or piston-based systems that prevent ingredient separation and ensure uniform dosing.

Without these adaptations, dosing units might struggle with clogging or uneven portioning. Modern systems integrate features like self-cleaning nozzles and variable pressure settings to handle varying ingredient textures. Some units also use pulsation control to regulate flow and prevent blockages.

Precision in viscosity handling ensures uniform portioning and reduces production downtime.

Hygiene, Material Standards, and Cleaning Systems

The choice of materials, surface design, and cleaning systems all impact the sanitation process and the overall efficiency of production.

Food-grade materials prevent contamination and ensure compliance with hygiene regulations. Stainless steel, particularly AISI 304 and AISI 316, is the industry standard because of its corrosion resistance and non-reactive properties.

Non-toxic and FDA-approved plastics are also used for specific components that require flexibility or chemical resistance. In the EU, adherence to EC 1935/2004 and EHEDG (European Hygienic Engineering & Design Group) guidelines ensure that all materials meet the highest food safety and hygiene standards.

Smooth surfaces and minimal crevices reduce the risk of bacterial growth. Rough or porous materials can trap food particles, creating ideal conditions for microbial contamination. Seamless welding, polished finishes, and rounded edges further improve cleanability.

Cleaning systems play a key role in maintaining sanitation without excessive downtime. Common systems include:

- Clean-in-Place (CIP): Uses automated flushing with detergents and sanitizers to remove residues without disassembling components.

- Sterilize-in-Place (SIP): Applies high-temperature steam or chemical sterilization to eliminate microbial contamination.

Easy disassembly is another factor that impacts hygiene and efficiency. Tool-free designs allow operators to quickly remove components for manual cleaning or inspection. This reduces downtime and ensures thorough sanitation between production runs.

Hygienic design in dosing units minimizes contamination risks and streamlines cleaning, ensuring both food safety and operational efficiency.

Automation and Control Features

Integrating with automated production lines enables dosing units to synchronize with conveyors, filling stations, and packaging systems to maintain efficiency and consistency.

Integrating with automated production lines enables dosing units to synchronize with conveyors, filling stations, and packaging systems to maintain efficiency and consistency.

Programmable Logic Controllers (PLCs) manage dosing parameters, controlling portion size, speed, and sequencing. They allow adjustments to be made in real-time, reducing waste and ensuring uniformity across batches.

Many dosing units feature touchscreen interfaces with recipe storage, enabling operators to switch between different formulations quickly without manual recalibration.

To improve accuracy, sensors and weight checks continuously monitor ingredient flow. These systems detect deviations and make automatic corrections, reducing the risk of under- or over-dosing.

Automated dosing units increase production efficiency by reducing human intervention, improving accuracy, and enabling seamless process integration.

Real-time monitoring also provides data for process optimization, helping to identify inefficiencies before they impact production.

The benefits of automation extend beyond accuracy. By reducing manual handling, dosing units improve hygiene and lower contamination risks. Automated cleaning systems further support compliance with food safety standards, streamlining maintenance between production runs.

How to Choose the Right Dosing Unit for Your Production Needs

Selecting the right dosing unit ensures efficiency, precision, and seamless integration into your ready meal production line. Several factors determine the best fit for your operation.

First, assess your production requirements.

Identify the types of ingredients you need to dose—liquids, semi-solids, or solids—and their specific handling needs. Consider portion sizes, whether small, precise amounts, or bulk quantities. Evaluate viscosity, particle size, and whether specialized dosing mechanisms, such as pumps for liquids or volumetric cups for solids, are necessary.

If your production line processes multiple ingredients, ensure the dosing unit can accommodate this without compromising accuracy.

Integration with your tray handling and packaging systems is also critical. The dosing units have to align with existing filling, sealing, and packaging machinery. Synchronization between dosing speed and conveyor movement prevents misalignment and spillage.

Look for adjustable dosing heads or modular designs that adapt to different tray sizes and configurations.

Automation features, such as sensor-based filling, help maintain consistency and minimize manual intervention.

Flexibility and scalability are key for adapting to future production demands. A modular dosing system allows for expansion, such as adding extra dosing heads or incorporating new ingredients.

The ability to switch between recipes and portion sizes with minimal downtime improves efficiency. Systems with recipe storage and programmable settings streamline batch production and reduce setup time.

Technological advancements further improve dosing unit performance:

- Automation and AI-driven dosing optimize portioning accuracy in real time, adjusting for ingredient flow, weight, and consistency variations. This ensures precision while reducing labor dependency.

- IoT integration and predictive maintenance enable real-time performance monitoring and diagnostics. Predictive maintenance detects potential failures before they cause downtime, while cloud-based monitoring allows remote control and process optimization.

- Energy-efficient and sustainable designs lower operational costs. Features like low-power motors and optimized dosing cycles reduce energy consumption. Sustainable materials and eco-friendly cleaning processes contribute to greener production. Precise dosing minimizes ingredient waste, improving cost efficiency and sustainability.

Choosing the right dosing unit requires balancing precision, integration, scalability, and technological advancements to meet production demands efficiently.

Scaling Your Production with Kometos’ Flexible Dosing Solutions

Selecting the right dosing unit means considering ingredient types, portioning needs, packaging compatibility, and future scalability. For manufacturers handling multi-component meals like pasta, rice, vegetables, and sauces, a system that ensures precise portioning, seamless tray integration, and flexibility for different recipes is key.

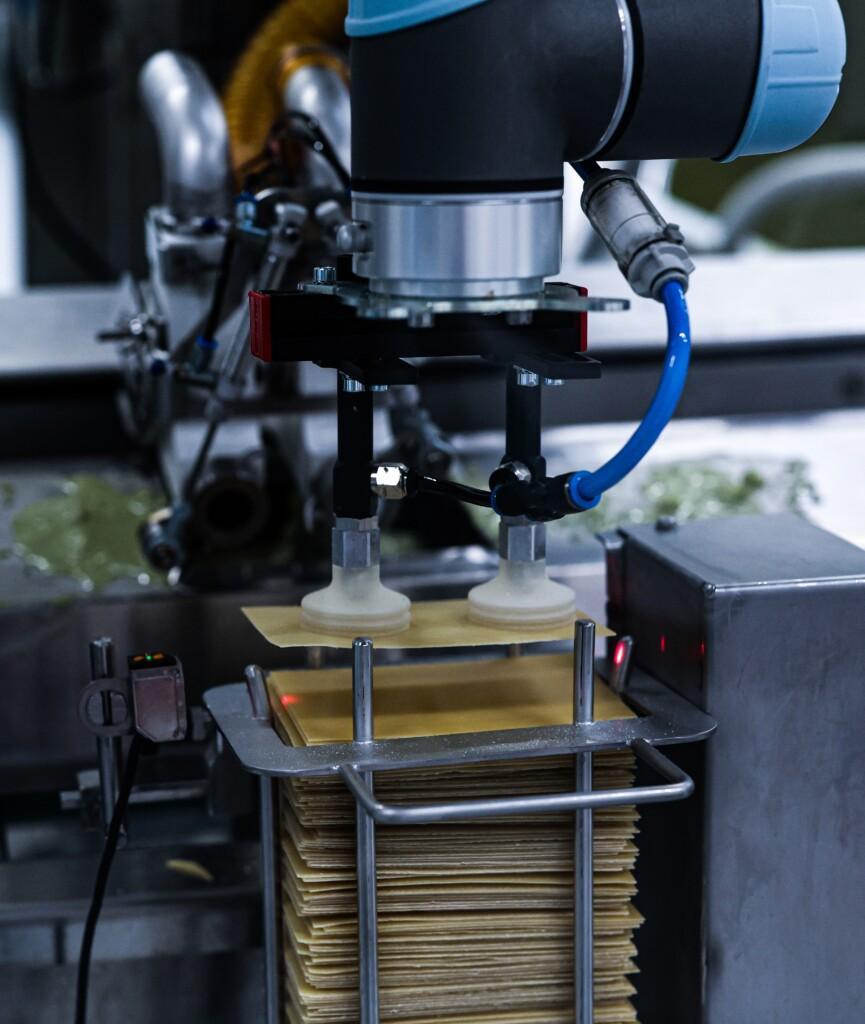

One of the biggest challenges in dosing pasta and rice is their stickiness—many dosing systems struggle to dispense these ingredients consistently without clumping or clogging. Kometos Finntray dosing systems are engineered to handle a wide range of ingredients, including those with challenging textures, ensuring smooth, accurate portioning across all meal components.

With specialized dispensers for both solid and semi-liquid ingredients, our systems handle varied viscosities while maintaining high-speed, precise dosing. The modular design allows for easy scaling and customization, supporting multiple ingredients on a single production line.

Additionally, automation features, including sensor-based filling and programmable recipe storage, help streamline operations, reduce downtime, and ensure consistent portioning across every batch.

If you’re considering an optimized dosing and tray-handling solution, get in touch to discuss a system tailored to your needs.

FAQ

What is a dosing unit?

A dosing unit is a specialized device that precisely measures and dispenses controlled amounts of ingredients in food production. It ensures accurate portioning of liquids, semi-solids, and solids, maintaining consistency, efficiency, and hygiene in large-scale ready meal manufacturing.

What is dosing in manufacturing?

Dosing in manufacturing refers to the automated or controlled process of dispensing specific ingredient quantities into a production line. It ensures uniformity in product composition, minimizes waste, and optimizes efficiency, particularly in ready meal production where multiple components require precise portioning.

What is the purpose of dosing?

The purpose of dosing is to maintain product consistency, reduce ingredient waste, and enhance production efficiency. In food manufacturing, it ensures that each portion meets quality standards, supports hygiene compliance, and integrates seamlessly with automated packaging systems.

What is a dosing device?

A dosing device is an equipment component used to measure and dispense precise ingredient quantities. It can operate via volumetric, gravimetric, or pump-based mechanisms, ensuring accurate portioning of various food components in high-speed, large-scale production environments.