How Dosing Systems Ensure Accuracy in Ready Meal Production

Precision is everything in food production. Too much sauce, not enough seasoning, or an inconsistent texture can hurt both quality and efficiency. This is where dosing systems come in. These automated systems control the exact amount of ingredients added at each step, ensuring consistency, reducing waste, and improving operational speed.

This article breaks down what dosing systems are and how they work in food production.

What Is a Dosing System?

A dosing system is an automated solution that measures and dispenses precise portions of ingredients into ready meal packaging. It ensures accuracy and repeatability for solid, semi-liquid, and liquid components such as pasta, rice, vegetables, and sauces.

By precisely controlling portion sizes, dosing systems help maintain consistency across large production runs.

The system operates using a combination of pumps, sensors, control units, and dispensing mechanisms. Ingredients are stored in a reservoir or feeder system and transported through pumps or conveyors to the dispensing unit.

Based on pre-set parameters, the system doses ingredients according to volume, weight, or flow rate, ensuring each meal receives the correct portion.

Dosing systems play an important role in multiple areas:

- Consistency and Quality Control – Every meal contains the same portion size, maintaining uniformity in taste and appearance.

- Efficiency and Speed – Automation allows rapid portioning, reducing manual labor and increasing production capacity.

- Waste Reduction – Prevents over-portioning, minimizing ingredient loss and lowering costs.

- Hygiene and Compliance – Reduces direct human contact with food, helping meet food safety regulations.

Compared to manual portioning, dosing systems significantly improve accuracy and efficiency. Manual dosing relies on human workers, increasing the risk of inconsistencies and errors.

Automated systems, however, provide precise portioning at high speeds while reducing labor costs, making them important for large-scale production.

Dosing systems ensure precise ingredient control, improving efficiency, consistency, and food safety.

Common Types of Dosing Systems in Ready Meal Production

Type 1. Gravimetric dosing systems

Gravimetric dosing systems ensure precise ingredient portioning by using weight-based measurement. These systems continuously weigh ingredients before dispensing them, adjusting flow rates in real-time to maintain accuracy.

These systems work well for ingredients that require high dosing accuracy, such as:

- Sauces and gravies, where consistency in portion size affects both taste and presentation.

- Liquid components, including oils and broths, where even slight deviations can impact the final product.

- Cost-intensive ingredients, ensuring minimal waste and optimized ingredient usage.

The advantages of gravimetric dosing systems include:

- High precision, with dosing continuously adjusted based on real-time weight readings.

- Cost efficiency, reducing ingredient overuse and minimizing waste.

- Compliance assurance, ensuring food safety regulations are met through accurate portion control.

However, these systems also present challenges:

- Slower processing speeds, as continuous weighing and adjustments take time.

- Complex calibration and maintenance, requiring regular checks to maintain accuracy.

Gravimetric dosing systems optimize ingredient control by continuously adjusting flow rates based on real-time weight measurements.

Type 2. Volumetric dosing systems

Volumetric dosing systems portion ingredients based on volume instead of weight. They use fixed-volume chambers that fill with a set amount of an ingredient before dispensing it into trays or containers.

Volumetric dosing systems portion ingredients based on volume instead of weight. They use fixed-volume chambers that fill with a set amount of an ingredient before dispensing it into trays or containers.

This method ensures consistent portion sizes, though it does not account for variations in ingredient density.

These systems are commonly used for bulk solid or semi-solid ingredients such as pasta, rice, and diced vegetables. They are well-suited for high-speed, repetitive portioning where minor fluctuations in weight do not affect the final product’s quality.

In large-scale production, they help maintain efficiency while keeping throughput high.

Volumetric dosing systems offer several advantages:

- Higher speed than gravimetric dosing, making them ideal for fast-paced production lines.

- Simpler mechanics, resulting in lower maintenance demands and reduced downtime.

- Scalability, as they work well in operations where minor portion variations are acceptable.

However, they also come with challenges:

- Less precision Because of density variations, which can lead to small inconsistencies in portion weight.

- Potential need for manual checks to ensure consistency over extended production runs.

For manufacturers prioritizing speed and efficiency over absolute precision, volumetric dosing systems provide a practical solution.

Volumetric dosing systems maximize production speed while maintaining consistent portion sizes.

Type 3. Multi-head weigher systems

Multi-head weigher systems use multiple weighing heads to measure and combine portions, achieving exact target weights before dispensing. Each weighing head operates independently, allowing the system to optimize ingredient distribution while minimizing waste.

Multi-head weigher systems use multiple weighing heads to measure and combine portions, achieving exact target weights before dispensing. Each weighing head operates independently, allowing the system to optimize ingredient distribution while minimizing waste.

These systems are particularly useful for multi-component meals. They ensure each portion contains the correct balance of proteins, vegetables, and starches. This makes them ideal for dishes where consistency is critical, such as pre-packaged salads, frozen meals, or ready-to-eat bowls.

Key advantages of multi-head weighers include:

- High precision, ensuring accurate ingredient distribution across multiple trays.

- Efficiency in complex meal compositions, handling multiple ingredients at once.

- Reduced product giveaways, minimizing excess portions to control costs.

However, these systems require a more complex setup compared to single-stream dosing methods. Calibration has to be precise to maintain accuracy, and the initial investment is higher. Despite this, the long-term savings in ingredient control and waste reduction often justify the cost.

Multi-head weigher systems combine accuracy and efficiency, making them important for multi-ingredient ready meals.

Key Components of a Dosing System

Pump Mechanism

The pump mechanism in dosing systems controls the flow of liquid and semi-liquid ingredients, ensuring that each portion dispensed into trays meets precise volume requirements.

By regulating flow rate and pressure, the pump mechanism prevents inconsistencies that could compromise product quality.

Different pump types serve specific dosing needs:

- Peristaltic pumps handle shear-sensitive ingredients like sauces, preventing damage to delicate textures.

- Diaphragm pumps work well with thick or viscous ingredients such as gravy, maintaining a steady and controlled flow.

- Piston pumps generate high pressure for dosing dense pastes or heavy mixtures, ensuring accurate portioning even with challenging consistencies.

A well-designed pump mechanism improves efficiency in automated production lines. It helps maintain consistent portioning, reduces ingredient waste by minimizing over-dosing, and can be customized for different viscosities and food textures. These advantages make dosing systems more reliable and cost-effective.

However, pump mechanisms require regular maintenance and cleaning to prevent clogging, especially when handling thick or particulate-rich ingredients. Some formulations might also need specialized pump configurations to preserve texture and flow characteristics.

The right pump mechanism ensures both precision in portioning and efficiency in ready meal production.

Sensors and Control Units

Sensors and control units are important for ensuring dosing accuracy in ready meal production. They monitor ingredient flow, regulate portion sizes, and automate real-time adjustments to maintain consistency across production cycles.

Different types of sensors contribute to precise dosing:

- Weight sensors measure portions to match target weights, ensuring each meal contains the correct amount of ingredients.

- Flow sensors regulate ingredient movement, preventing irregular distribution.

- Pressure sensors help stabilize dosing, especially for thick or semi-solid foods, by adjusting pump force as needed.

Control units process data from these sensors and adjust dosing parameters accordingly. Centralized systems, such as programmable logic controllers (PLCs), manage pump speed, portion size, and flow rate.

These units also store pre-programmed recipes, ensuring repeatability across batches. Many control systems integrate with other production line equipment, synchronizing tray handling, sealing, and packaging for seamless operation.

Using sensors and control units improves dosing system efficiency in several ways:

- Higher precision reduces ingredient waste and ensures product consistency.

- Real-time monitoring allows for immediate adjustments, minimizing errors.

- Reduced manual intervention helps meet hygiene and safety standards.

However, these systems require regular calibration to maintain accuracy. Additionally, their complexity might necessitate technical expertise for troubleshooting and maintenance.

Automated control systems improve dosing accuracy while reducing production inconsistencies.

Nozzles and Dispensing Mechanisms

Nozzles and dispensing mechanisms control how ingredients are delivered into trays or containers, ensuring precision and consistency in ready meal production. Their design minimizes clogging, dripping, and contamination, which is important for maintaining food quality and production efficiency.

Different dispensing mechanisms serve specific purposes:

- Fixed nozzles work best for high-speed, continuous production lines where ingredients are dispensed in a steady flow.

- Rotary nozzles spread ingredients evenly over a surface, making them ideal for applications like sauce or garnish distribution.

- Pneumatic or pressure-controlled nozzles regulate liquid flow with precision, preventing over- or under-dispensing.

Nozzles have to handle a range of food textures, from thin liquids to thick, chunky mixtures. Anti-drip designs prevent ingredient loss and contamination, while adjustable flow settings allow portion sizes to be tailored to different recipes.

Their strengths include:

- Accurate and clean dispensing, reducing spillage and product waste.

- High-speed operation, keeping up with fast-paced production lines.

- Improved hygiene, as controlled dispensing lowers the risk of bacterial contamination.

Nonetheless, regular cleaning is necessary to prevent ingredient buildup, and certain high-viscosity foods might require specialized nozzle designs to ensure smooth flow.

Nozzles determine both the precision and efficiency of ingredient dispensing in ready meal production.

Wrapping Up

Dosing systems play a critical role in ready meal production, ensuring precise portioning, reducing waste, and maintaining product consistency.

By automating ingredient dosing, manufacturers can improve production efficiency, hygiene, and quality control, all while meeting strict food industry standards.

From gravimetric and volumetric dosing to multi-head weighing systems, modern solutions provide adaptable and scalable options for different meal compositions.

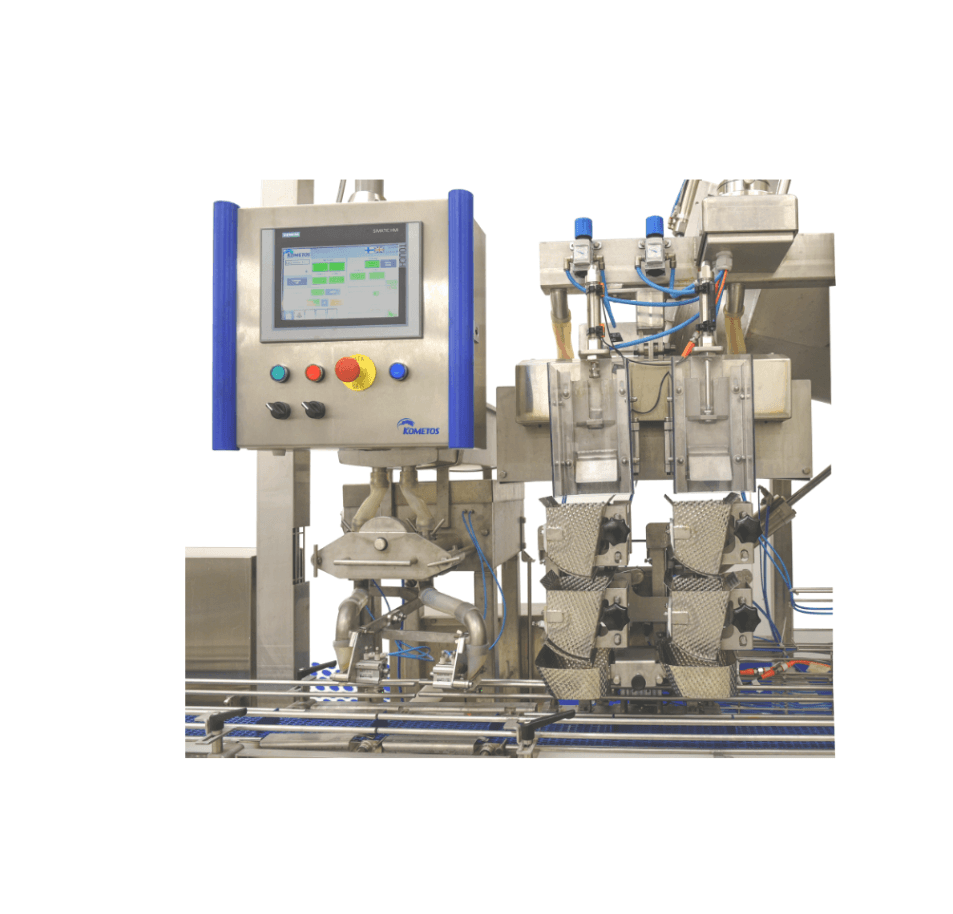

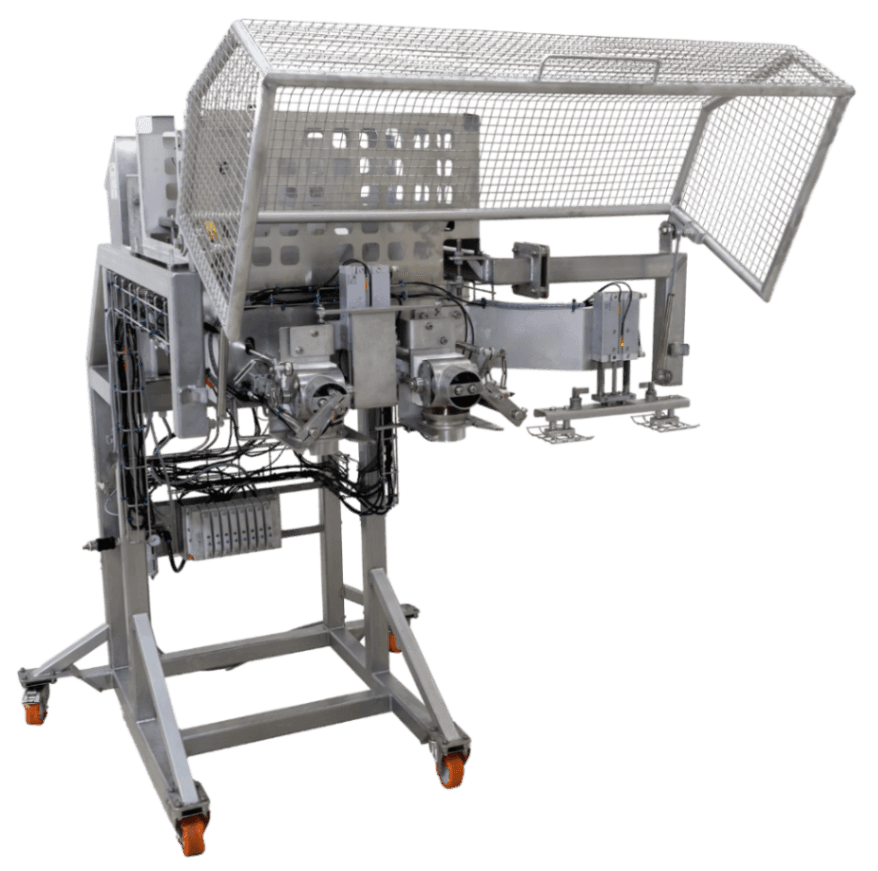

For manufacturers aiming to enhance efficiency and precision in ready meal production, Kometos Finntray offers advanced dosing and packaging solutions. Designed to handle various components such as pasta, rice, vegetables, and sauces, our systems ensure accurate portioning and maintain strict hygiene standards.

With a flexible and customizable approach, we design and tailor machines and production lines to meet the specific needs of both small producers and large-scale manufacturers, ensuring seamless integration and optimal performance.

FAQ

What is a dosing system?

A dosing system is an automated solution designed to measure and dispense precise portions of ingredients in ready meal production. It ensures consistent portioning of components like pasta, rice, vegetables, and sauces, improving production efficiency, reducing waste, and maintaining product quality.

What is the function of the dosing system?

A dosing system’s primary function is to accurately portion and dispense ingredients into trays. It automates the process to ensure uniformity, minimize waste, and enhance efficiency in food production while maintaining strict hygiene and food safety standards.

How does a dosing unit work?

A dosing unit controls the flow of ingredients using pumps, sensors, and dispensing mechanisms. It measures portions based on weight, volume, or flow rate, ensuring precise filling into trays while integrating with automated food packaging lines.

What is the difference between metering and dosing?

Metering refers to continuous ingredient flow regulation, while dosing involves dispensing a precise, pre-set amount. In ready meal production, dosing ensures controlled portioning, whereas metering helps regulate ingredient supply.

What is an automatic dosing system?

An automatic dosing system uses sensors and control units to adjust ingredient flow in real-time, ensuring precise and repeatable portioning. It integrates with production lines for seamless operation, improving speed, consistency, and hygiene in large-scale ready meal production.