Boosting Efficiency with Industrial Automatic Dosing Lines

A perfectly portioned meal doesn’t happen by chance—it’s the result of precise engineering and seamless automation. Behind every well-balanced ready meal is a system designed to measure, dispense, and assemble ingredients with absolute accuracy. Automatic dosing lines transform raw components into consistent, high-quality meals by eliminating guesswork and inefficiencies.

From pasta and vegetables to sauces and proteins, these systems ensure every portion meets exacting standards while optimizing production flow.

This article unpacks the mechanics of industrial automatic dosing lines, breaking down their key components and their impact on efficiency in large-scale ready meal production.

Why Automatic Dosing Lines Matter in Food Production

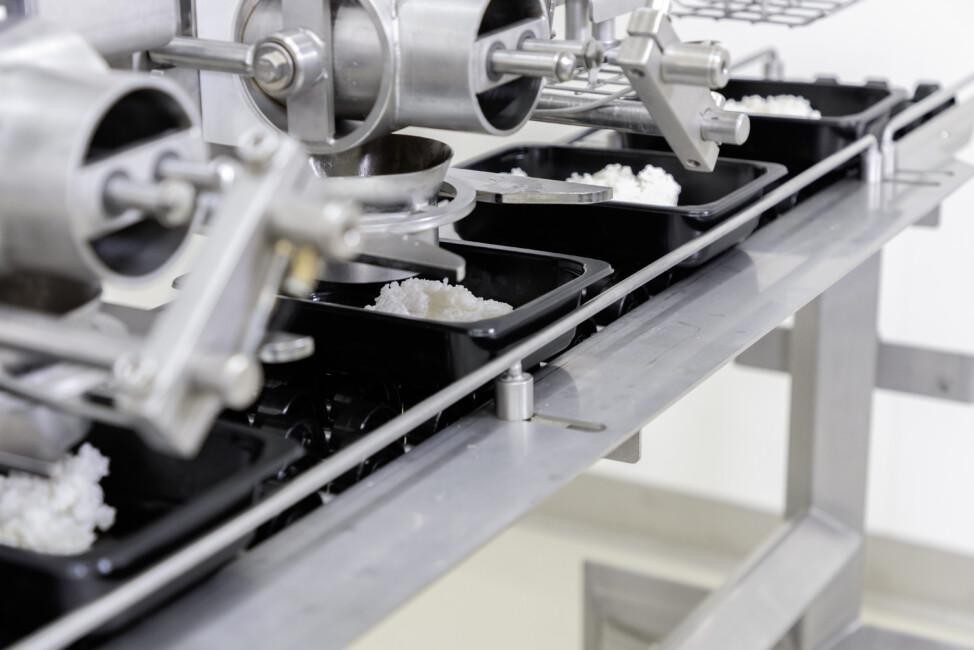

Automatic dosing lines measure and dispense exact quantities of ingredients, such as sauces, grains, and vegetables, into trays for ready meals. By integrating dosing heads, flow meters, and control systems, they achieve consistent portioning while seamlessly working with tray packaging lines.

Precision dosing is important for maintaining product quality. It ensures that each meal contains accurate proportions of ingredients, leading to consistency in taste, texture, and nutritional content. Automation eliminates human errors in portioning, reducing variability and helping manufacturers meet regulatory requirements for labeling and nutrition claims.

Efficiency gains are another major advantage. Automated dosing significantly increases production speed, allowing you to maintain high throughput while ensuring quality. It reduces reliance on manual portioning, lowering labor costs and minimizing production time. Additionally, these systems integrate smoothly with continuous production lines, preventing bottlenecks and improving workflow.

Minimizing ingredient waste is a direct benefit of precise dosing. Over-portioning increases costs, while under-portioning can lead to customer dissatisfaction and compliance issues. Automated systems use exact ingredient measurements to reduce waste and optimize cost efficiency. They also improve inventory management by providing accurate ingredient tracking, helping with production planning.

Food safety and hygiene are critical in food manufacturing. Automatic dosing lines reduce human contact with ingredients, lowering contamination risks. Built with stainless steel and other hygienic materials, they are easy to clean and meet industry standards for sanitation. These systems help ensure compliance with HACCP and ISO food safety regulations by maintaining controlled ingredient handling.

Seamless integration with tray packaging is another key advantage. Automated dosing lines work in coordination with tray dispensers, sealing machines, and conveyors to improve production efficiency. They support various packaging materials, including plastic, aluminum, and cardboard, allowing flexibility in product offerings. Additionally, they enable quick recipe changes and batch adjustments, helping manufacturers respond to evolving consumer demands.

Flexibility in portioning and meal configurations is equally essential. In large-scale production, meal composition isn’t always fixed—adjustments may be required based on product design or consumer preferences. If a manufacturer decides that meatballs should be placed on the left side of the tray and mashed potatoes on the right instead of vice versa, the dosing system must accommodate these changes seamlessly.

Beyond positioning, dosing lines must be adaptable to different meal compositions and portion sizes. A single machine might need to dispense pasta Bolognese today and rice with creamy chicken sauce tomorrow, requiring precise adjustments for ingredient types, placement, and weights. If the pasta Bolognese meal is 500g while the chicken with rice meal is 400g, the system must recalibrate to ensure consistent, accurate dosing for each product without slowing production.

Automated dosing lines improve food production by ensuring precision, efficiency, and compliance with safety standards.

Core Components of an Automatic Dosing Line

1. Dosing Heads and Their Role in Portion Control

Dosing heads are responsible for measuring and dispensing precise portions of food ingredients. They ensure that each tray receives the correct amount of food components, maintaining consistency in portion sizes. Their design allows them to handle a wide range of food consistencies, from solid ingredients to semi-liquid components like gravies and dressings.

Different types of dosing heads are used depending on the texture and flow characteristics of the food being dispensed:

- Volumetric dosing heads measure portions based on volume, ensuring uniform distribution of solid ingredients such as pasta, rice, and diced proteins.

- Piston-based dosing heads are designed for semi-liquid foods, using a controlled pushing motion to dispense sauces, purees, and thicker liquids with precision.

- Gravity-fed dosing heads rely on controlled release mechanisms to dispense free-flowing ingredients like grains, shredded cheese, or diced vegetables.

Accuracy is critical in food production to maintain quality and minimize ingredient waste. Dosing heads are calibrated to release exact quantities, preventing over- or under-portioning. This precision ensures consistency in meal weight and appearance, which is important for both regulatory compliance and customer satisfaction.

Automation further improves accuracy by adjusting portion sizes based on predefined recipe parameters, eliminating variation between batches.

Precise dosing reduces ingredient waste, improves consistency, and improves overall production efficiency.

2. Control Panels and Automation Systems

Control panels and automation systems provide operators with the tools to configure, monitor, and adjust dosing processes with precision. Without these systems, maintaining consistency and efficiency in production would be far more challenging.

Control panels and automation systems provide operators with the tools to configure, monitor, and adjust dosing processes with precision. Without these systems, maintaining consistency and efficiency in production would be far more challenging.

Control panels act as the central interface for the dosing line. Operators use them to set portion sizes, modify flow rates, and track system performance in real-time. The panel continuously collects data, ensuring that each dose meets exact specifications. This level of control helps maintain product uniformity while reducing material waste.

Automation systems further improve dosing efficiency by integrating several key features:

- Programmable Logic Controllers (PLCs) automate dosing based on pre-set recipes. They adjust flow rates and portion sizes without manual intervention, ensuring consistency across production batches.

- Touchscreen user interfaces provide intuitive controls for operators. These screens make it easy to modify settings, troubleshoot issues, and monitor real-time performance.

- Recipe storage and selection allow for quick changeovers between different products. This flexibility reduces downtime and increases overall throughput.

Automated controls also bring significant operational benefits. By minimizing human intervention, they reduce dosing errors and improve accuracy. Remote monitoring capabilities enable predictive maintenance, identifying potential issues before they cause downtime. Additionally, dosing data is recorded for traceability, helping with quality control and regulatory compliance.

Automated control panels ensure precise dosing, reduce waste, and improve operational efficiency.

3. Flow Meters and Sensors for Accuracy

Flow meters measure the precise amount of liquid or semi-liquid ingredients dispensed per cycle. Sensors detect inconsistencies in portioning and adjust flow rates in real-time.

This combination ensures that every portion meets the required specifications, reducing waste and maintaining consistency across multiple trays.

Different types of flow meters and sensors serve specific roles in dosing systems:

- Magnetic flow meters measure liquid and semi-liquid ingredients by detecting the movement of conductive fluids. They provide precise volume flow measurements without obstructing the flow path.

- Weight-based sensors ensure solid components, such as rice or vegetables, meet exact portioning requirements by continuously measuring the weight of dispensed ingredients.

- Optical sensors detect blockages or irregularities in the dosing process. If they identify inconsistencies, they trigger adjustments or halt operations to prevent defective portions.

Sensor-based monitoring provides several advantages:

- Reduces ingredient waste by keeping portions within target weight and volume.

- Enables automatic and simultaneous corrections, ensuring consistent product quality.

- Minimizes production downtime by preventing portioning errors before they lead to disruptions.

Precision dosing relies on flow meters and sensors to maintain accuracy, reduce waste, and optimize production efficiency.

4. Tray Handling and Sealing Integration

Automated tray handling systems position each tray precisely under dosing stations, reducing the need for manual adjustments. This consistency prevents misalignment, ensuring that ingredients are dispensed accurately.

By automating this step, production lines can operate at higher speeds without sacrificing portion control or efficiency. Additionally, the automated movement of trays from dosing to sealing stations reduces handling errors and contamination risks.

Sealing and packaging systems work in tandem with tray handling to maintain product integrity. Once trays are filled, they have to be correctly aligned for sealing methods such as heat sealing, vacuum sealing, or film application. Proper alignment prevents ingredient spillage and ensures airtight seals, which help preserve freshness and hygiene.

Integration with automated sealing equipment also minimizes downtime, as the system can quickly adapt to different sealing requirements without manual intervention.

To accommodate various product formats, automated dosing lines support a range of tray materials, including plastic, aluminum, and cardboard. Adjustable tray positioning mechanisms allow for different portion sizes and meal configurations, making it easier to switch between product variations.

This flexibility is especially valuable in facilities that produce multiple recipes, as it enables rapid changeovers without significant reconfiguration.

Precise tray handling and seamless sealing integration keep production lines running efficiently while maintaining product quality.

How Automatic Dosing Systems Function in Industrial Settings

Automatic dosing systems play a key role in industrial food production by ensuring precise ingredient portioning at high speeds. These systems integrate seamlessly into large-scale ready meal production lines, connecting with both upstream ingredient preparation and downstream packaging processes.

In high-volume food production, automated dosing lines enable continuous operation, allowing manufacturers to meet large-scale market demands efficiently. They work in sync with cooking and mixing systems to receive prepared ingredients and then distribute them into trays with high accuracy. Once dosing is complete, the trays move directly to sealing and labeling stations, maintaining a smooth workflow and reducing bottlenecks.

Scalability is another advantage. Modern dosing systems can be expanded or adjusted based on production needs. Whether accommodating higher output volumes or adapting to different meal configurations, these systems offer flexibility without compromising speed or accuracy.

Synchronization between dosing, tray handling, and sealing is important for maintaining consistency. Trays move through the dosing stations in a controlled sequence, ensuring each compartment receives the correct portion. Sensors and control systems monitor ingredient flow in real-time, making micro-adjustments as needed to maintain uniformity. After dosing, trays transition directly to the sealing station, preventing spillage and ensuring food safety.

Precision control is achieved through real-time monitoring. Flow meters, weight sensors, and vision systems continuously track portion accuracy, correcting any deviations instantly. Data logging further improves quality assurance, providing traceability for regulatory compliance. Additionally, predictive maintenance systems detect potential faults before they cause downtime, helping to keep production running without unexpected disruptions.

Boost Your Production Flow with Kometos’ Automated Dosing Technology

Every stage of industrial dosing, from ingredient measurement to seamless tray handling, relies on precision and automation.

Every stage of industrial dosing, from ingredient measurement to seamless tray handling, relies on precision and automation.

As manufacturers strive for efficiency, waste reduction, and strict hygiene compliance, selecting the right dosing system is essential. Automation not only streamlines production but also cuts costs by reducing manual stages and personnel management demands. Integrated dosing and packaging solutions enhance speed, accuracy, and food safety compliance.

For ready meal manufacturers looking for a high-performance dosing solution, Kometos Finntray offers an advanced approach to portioning and packaging.

Designed to handle multi-component meals such as pasta, rice, vegetables, and sauces, our dosing systems provide precise, hygienic, and efficient automation tailored for large-scale food production. With seamless integration into tray packaging, our systems support various materials, including plastic, aluminum, and cardboard, ensuring flexibility in production.

Contact us today to explore how Finntray can enhance your production line!

FAQ

What is an automatic dosing system?

An automatic dosing system is a precision-controlled solution that measures and dispenses ingredients in food production. It ensures accurate portioning of components like pasta, rice, vegetables, and sauces in ready meal manufacturing, integrating seamlessly with tray handling and packaging systems to optimize efficiency and maintain hygiene standards.

Is auto dosing good?

Yes, auto dosing enhances efficiency, consistency, and food safety in industrial production. It minimizes waste, reduces manual errors, and speeds up processing, ensuring precise portioning for ready meals. Automated systems also improve hygiene by limiting human contact with food components, making them ideal for large-scale manufacturing.

What is auto dosing?

Auto dosing refers to the automated process of measuring and dispensing food ingredients in controlled portions. It ensures accuracy, efficiency, and hygiene in ready meal production, allowing manufacturers to produce consistent, high-quality meals while reducing waste and optimizing production speed.

How does a dosing system work?

A dosing system operates by automatically dispensing pre-measured amounts of ingredients into trays. It uses dosing heads, flow meters, and control systems to ensure precision. Trays move through the system in a synchronized manner, allowing for accurate portioning, minimal waste, and seamless integration with sealing and packaging units.

What is the standard dosing?

Standard dosing refers to the predefined portioning specifications set for each ingredient in a production line. In ready meal manufacturing, dosing standards ensure that each tray receives the exact amount of pasta, rice, vegetables, and sauces to maintain consistency, nutritional accuracy, and product quality across large-scale production.