Sulatus - Pakastus - Kohmetus

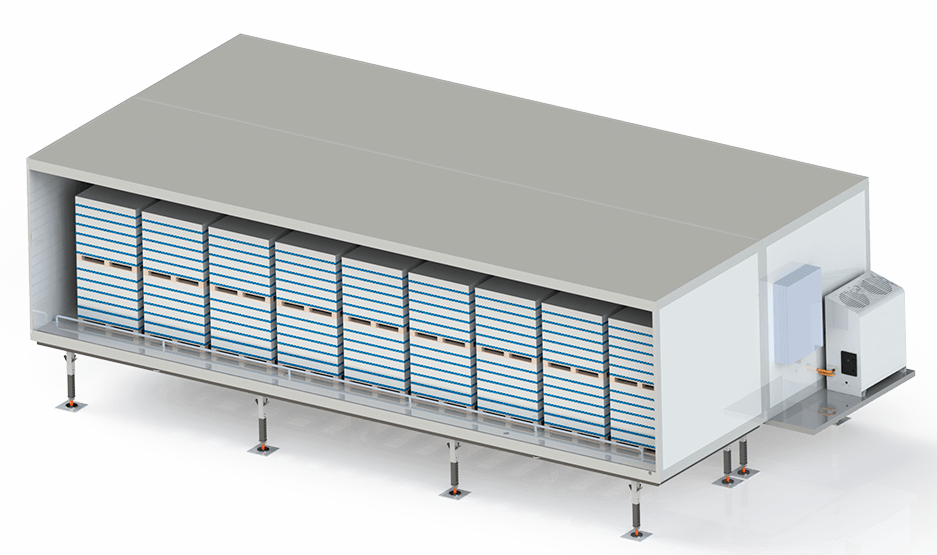

Kometos Finncold

Ratkaisuja elintarvikkeiden sulatukseen, pakastukseen ja kohmetukseen

Olisi tarpeesi sitten sulatus, pakastus tai kohmetus, toimitamme järjestelmät kaikkien elintarvikkeiden tehokkaaseen ja kontrolloituun temperointiin. Järjestelmämme on suunniteltu ja valmistettu varmistamaan korkealuokkainen ja energiatehokas lopputulos sekä mahdollisimman pieni hävikki.